WRX, WRX STI Control Arms

CB-ALY-0016K – WRX, WRX STI Standard Alignment Control Arms

CB-ALY-0017K – WRX, WRX STI Offset Caster Control Arms

Congratulations on your purchase of the COBB Tuning Roll Center Correction Kit! The following instructions will assist you through the installation process. Please read them BEFORE beginning the install to familiarize yourself with the steps and tools needed. If you feel you cannot properly perform this installation, we HIGHLY recommend you take the vehicle to a qualified and experienced automotive technician.

Table of Contents

While You're There

While doing this installation it's an easy time to do other installations such as sway bars and endlinks. Maintenance items such as the Balljoints that can be on their way out, or potentially damaged while removing the stock arms are a good idea to have on hand, or replace at the same time as they make the whole procedure easier.

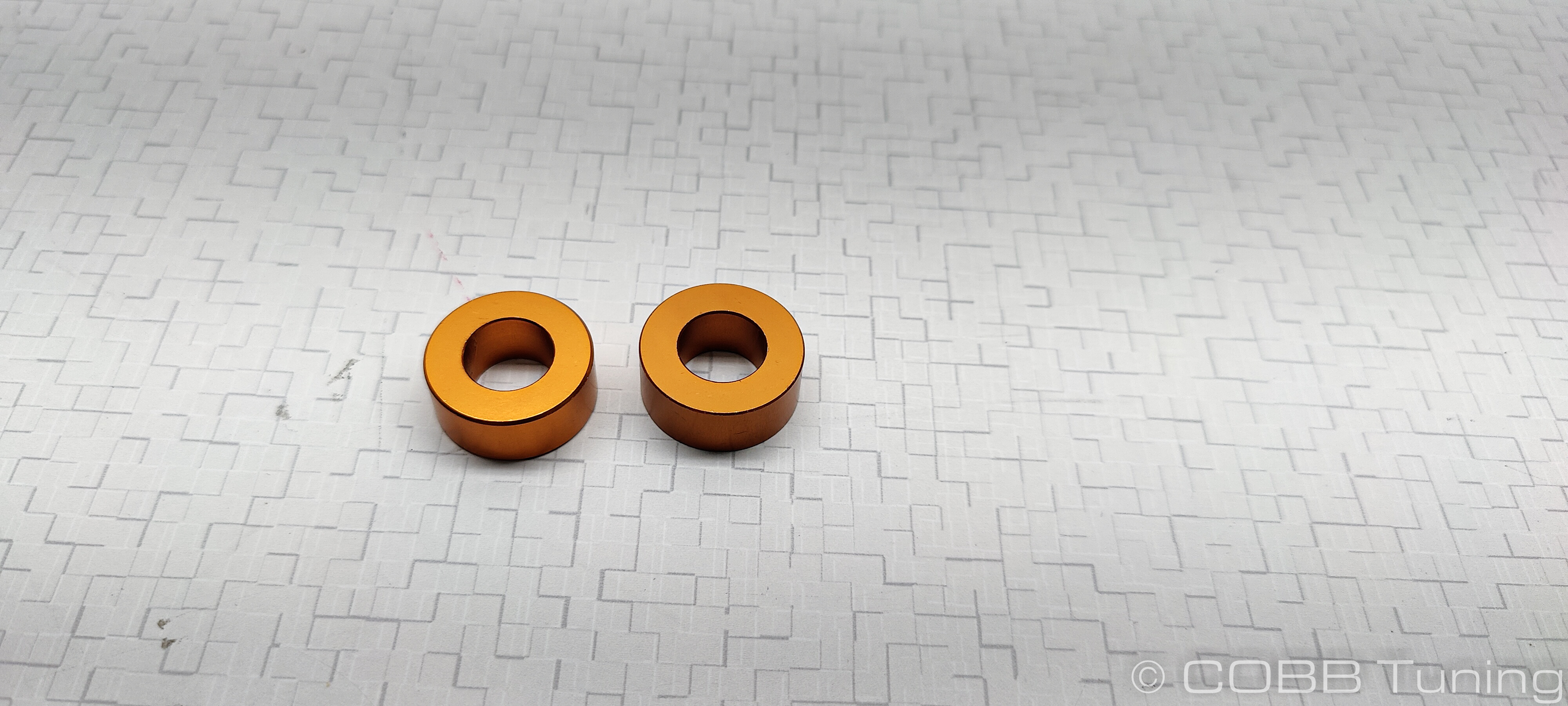

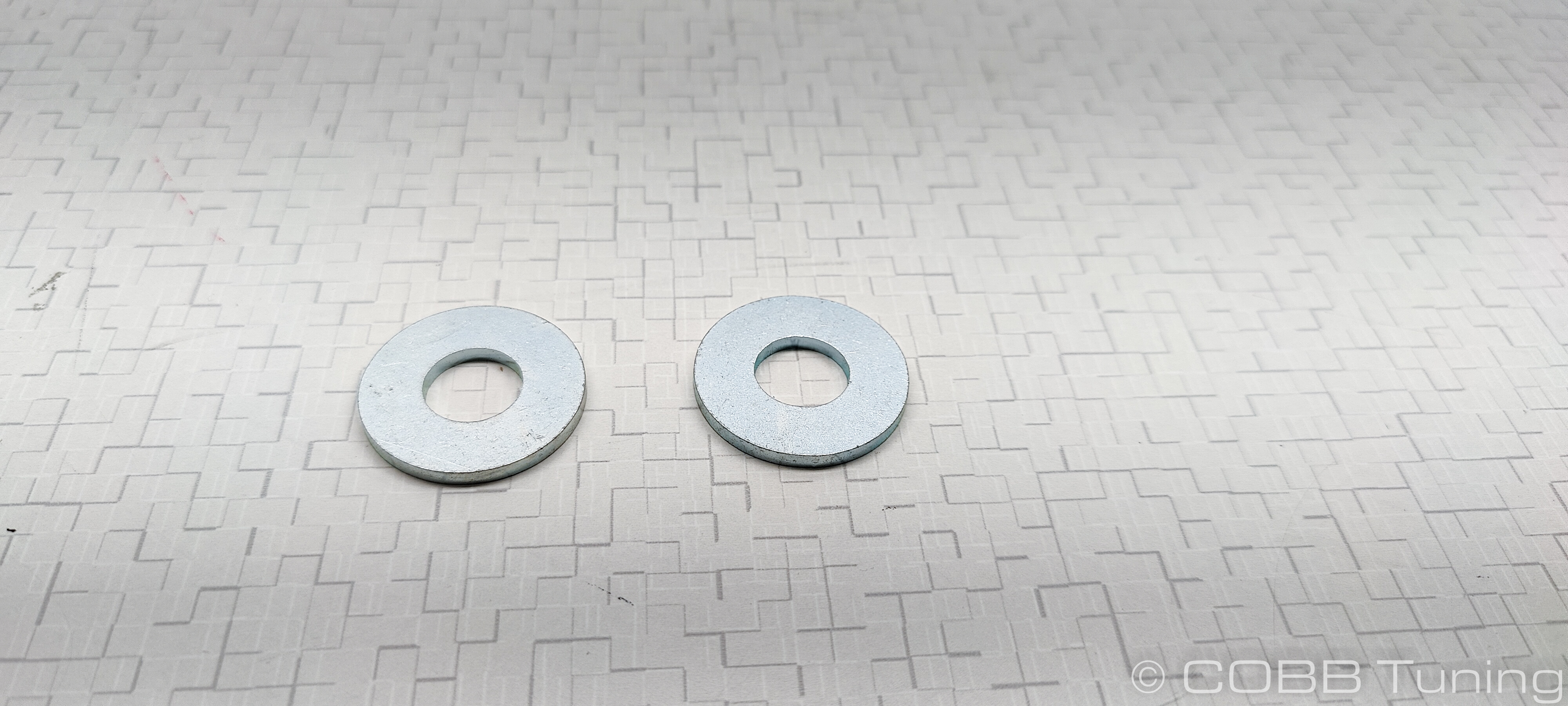

Parts List

Tools Needed

Sockets

1/2"

- 1/2" ratchet

- 1/2" 6" extension

- 1/2" 14mm socket

- 1/2" 19mm socket

Hand Tools

- Needlenose pliers

Wrenches

- 14mm combination wrench

- 17mm combination wrench

- 19mm combination wrench

OEM Style Handling

We recommend this setting for most users.

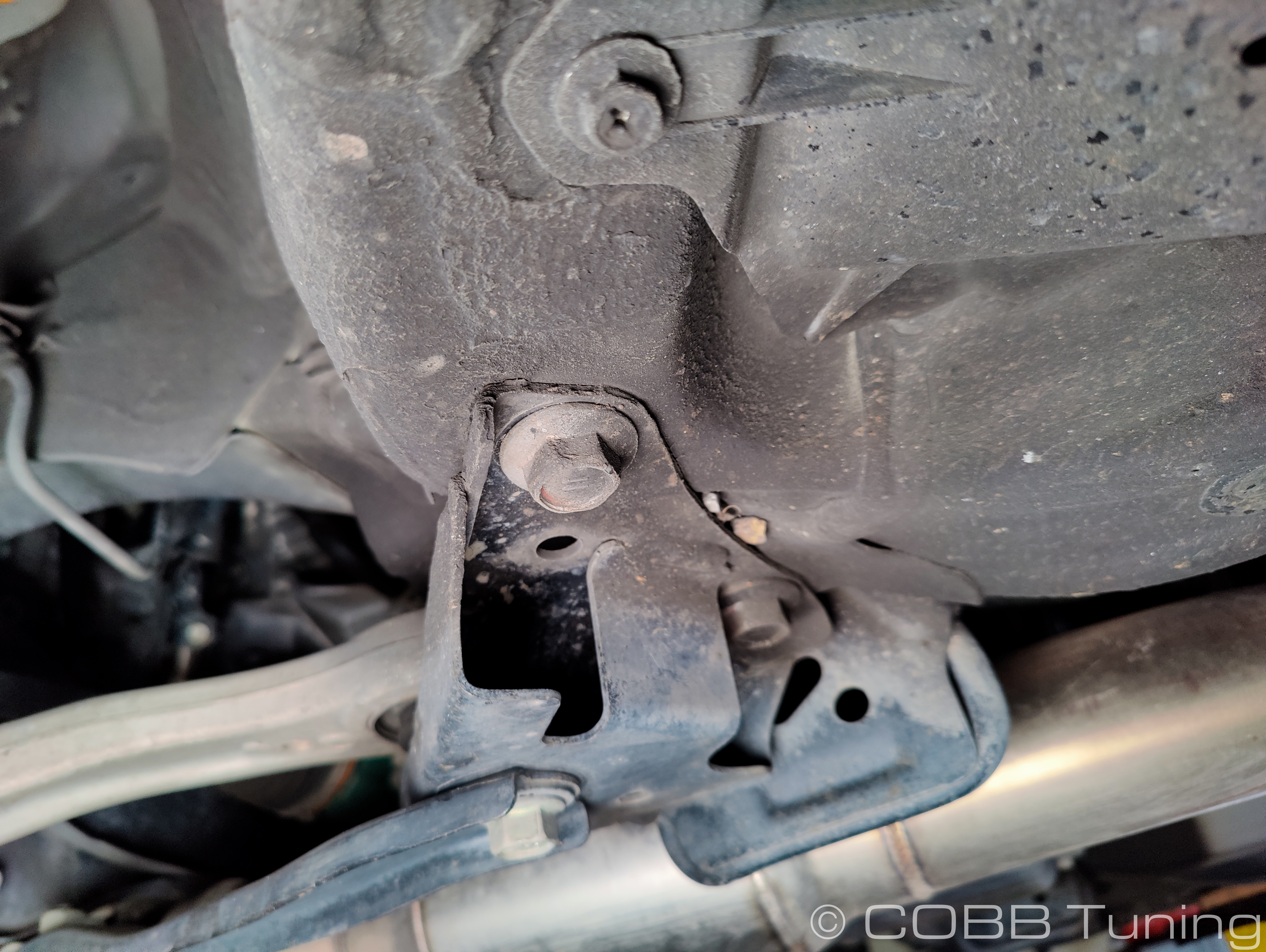

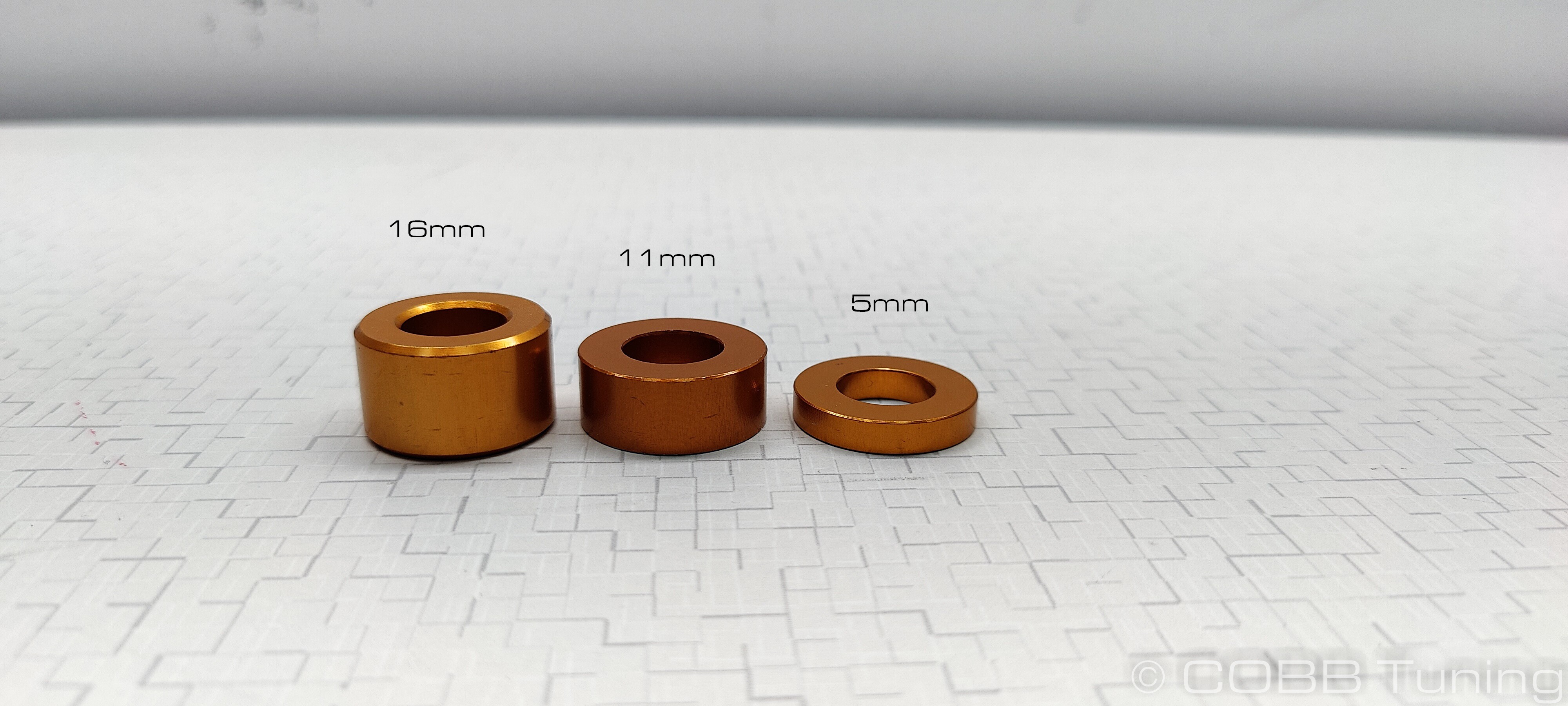

11-14 STI

- Main bushing between arm and vehicle: 16mm spacer

15-21 WRX and STI

- Main bushing between arm and vehicle: 16mm and 11mm spacer stacked

Anti-Dive

11-14 STI

- Main Bushing between arm and vehicle: 11mm Spacer

- Between arm and support bracket: 5mm spacer

15-21 WRX and STI

- Main bushing between arm and vehicle: 16mm spacer

- Between main bushing and support bracket: 11mm spacer

Anti-Lift

11-14 STi

- Main Bushing between arm and vehicle: 16mm spacer

- Between support bracket and vehicle: 5mm spacers

15-21 WRX and STI

- Main Bushing between arm and vehicle: 16, 11, and 5mm spacers stacked

- Between support bracket and vehicle: 5mm spacers

Front Suspension Torque Specs

| 1 | Lower BallJoint | 36.9 ft-lb | 50Nm |

| 2 | Front Swaybar Endlink to Control Arm | 44.3 ft-lb | 60Nm |

| 3 | Control arm front horizontal bushing | 70 ft-lb | 95Nm |

| 4 | Control arm rear vertical bushing | 103.3 ft-lb | 140Nm |

| 5 | Shorter bolts for control arm support bracket | 110 ft-lb | 150Nm |

| 6 | Control arm support bracket brace | 73.8 ft-lb | 100Nm |

| 7 | Wheels | 88.5 ft-lb | 120Nm |

Links

Contact Us:

COBB Customer Support

Web Support and Tech Articles: COBB Tuning Customer Support Center

Email: support@cobbtuning.com

Phone support available 9am to 6pm Monday-Thursday. 9am to 4pm Friday (CST)

866.922.3059

return to www.cobbtuning.com

Related content

Copyright 2025 © COBB Tuning Products LLC. All Rights Reserved. | www.cobbtuning.com