3V2650 - MQB Flex Fuel Kit

3V2650 – VW Flex Fuel Upgrade Kit

USDM GTI MK7, 7.5 2015-2021

USDM Golf R MK7, 7.5 2016-2019

USDM GLI A7, 2019-2021

USDM A3 2015-2021

USDM S3 2015-2020

Congratulations on your purchase of the COBB Tuning MQB Flex Fuel Kit! The following instructions will assist you through the installation process. Please read them BEFORE beginning the install to familiarize yourself with the steps and tools needed. If you feel you cannot properly perform this installation, we HIGHLY recommend you take the vehicle to a qualified and experienced automotive technician.

Table of Contents

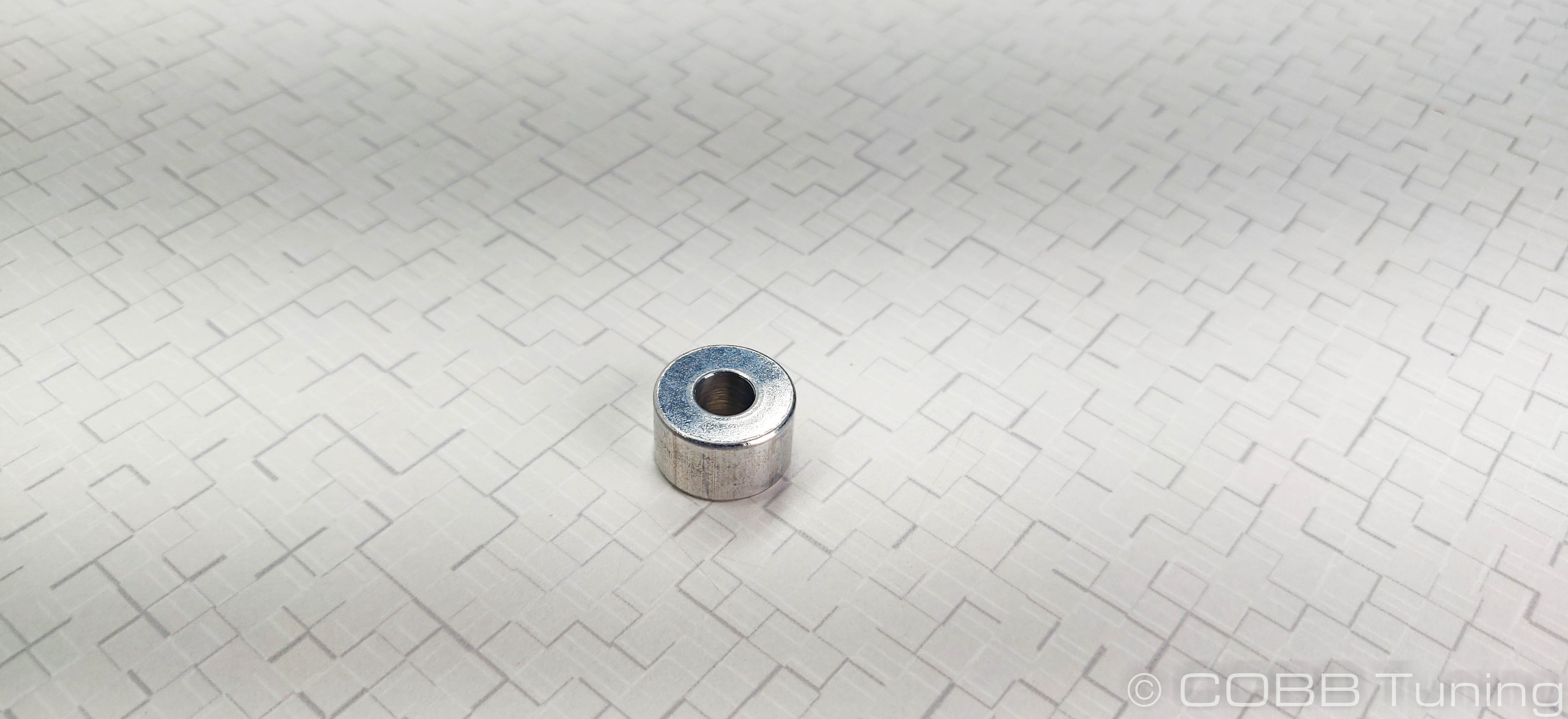

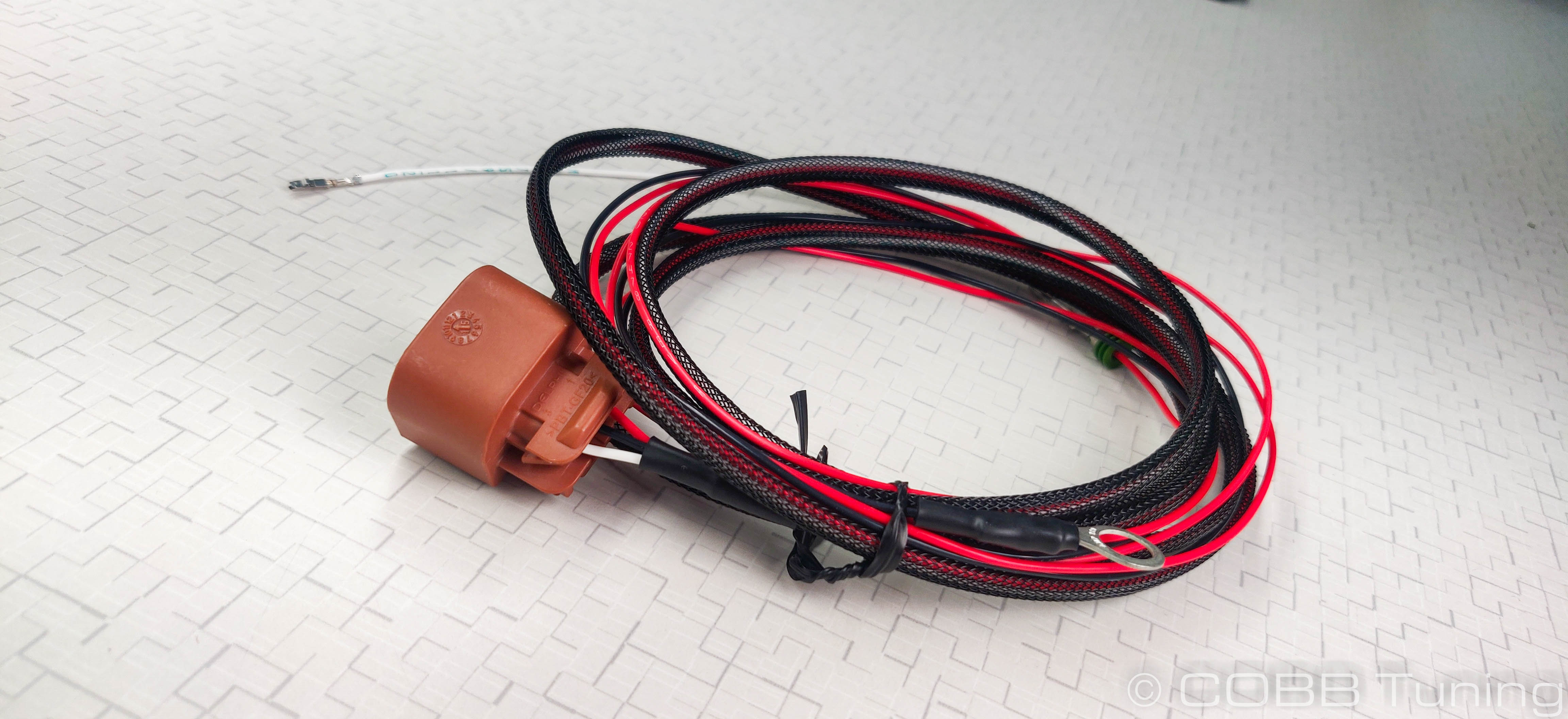

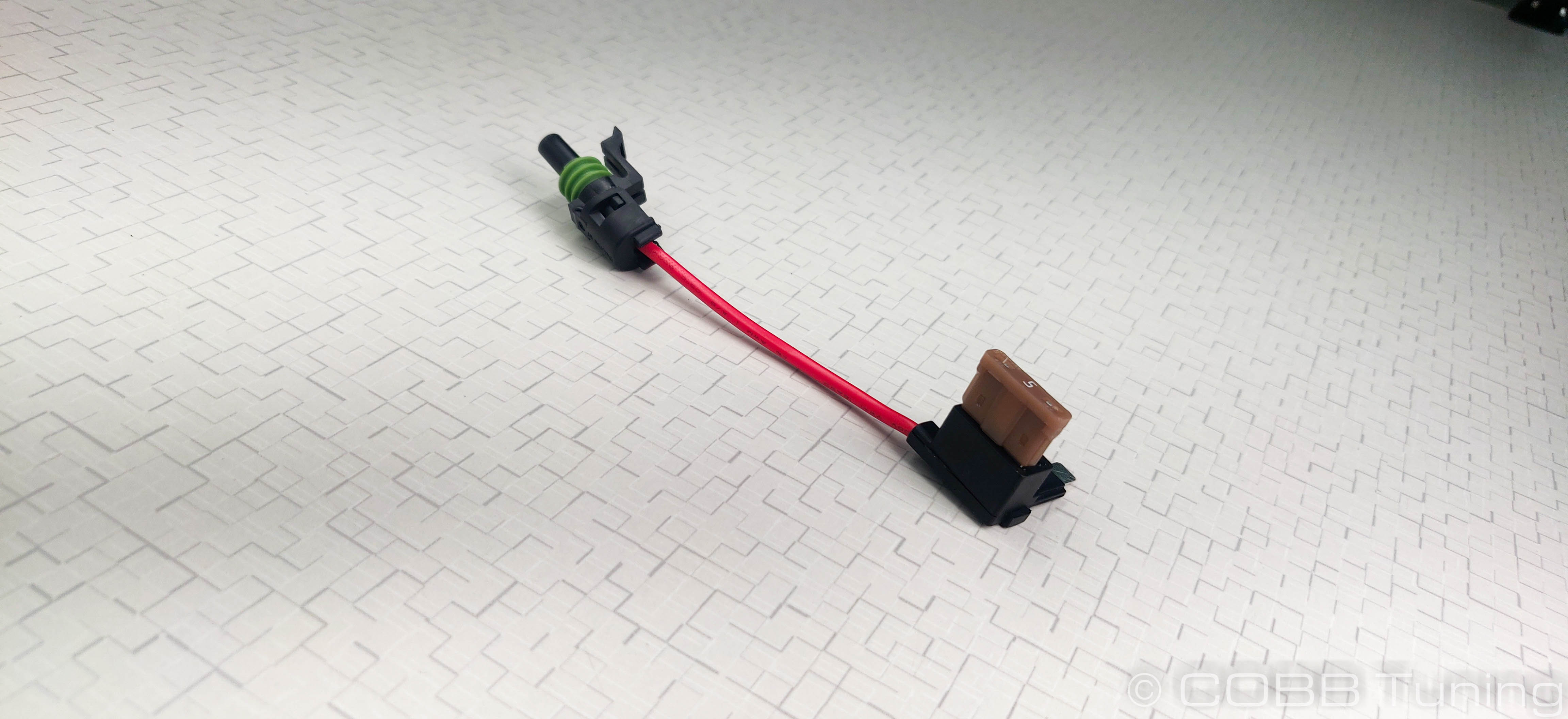

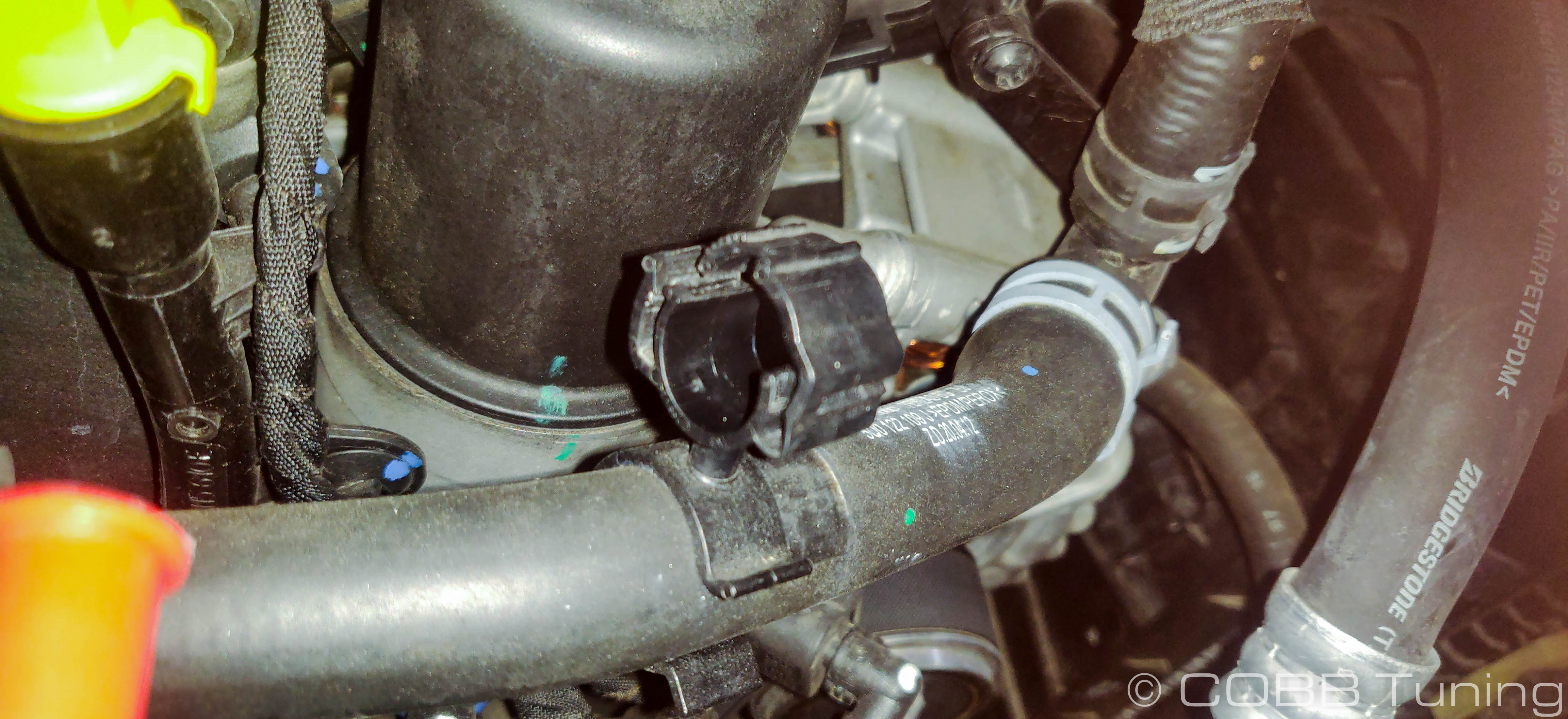

Parts List

Tools Needed

Sockets

3/8"

Hand Tools

- Phillips head screwdriver

- Flathead screwdriver

- Trim removal tool

Razor Blade or other safe cutting device

Links

Calibration Map Notes for Volkswagen

Helps to figure out which map you should be on given the parts installed to your car

COBB Customer Support Web Support and Tech Articles: COBB Tuning Customer Support Center Email: support@cobbtuning.com Phone support available 9am to 6pm Monday-Thursday. 9am to 4pm Friday (CST) 866.922.3059 return to www.cobbtuning.comContact Us:

Related content

Copyright 2025 © COBB Tuning Products LLC. All Rights Reserved. | www.cobbtuning.com