Subaru Differential Fuel Pressure Compensation

Subaru Differential Fuel Pressure Compensation Guide

Version 1.0

1/18/2016

Overview

One of the powerful options of the COBB Tuning Custom Features allows for the usage of a fuel pressure sensor to add a fuel pressure compensation into the overall fueling calculation and strategy. This is inherent to many OEM vehicles but a notable omission on all port-injected turbo Subarus.

Compensating Fuel Injector Scale against fuel pressure is a straightforward procedure. Bernoulli's Principle states that the flow of an orifice doubles every time the supply pressure quadruples. Thus, we are able to compensate Fuel Injector Scale against pressure changes with a good rate of accuracy using mathematics alone.

Differential Fuel Pressure is calculated by measuring fuel pressure via the newly added sensor, individually smoothing it and MRP (manifold relative pressure) which is already calculated by the ECU (manifold absolute pressure - barometric pressure), then subtracting fuel pressure minus MRP. From there, we can calculate a Differential Fuel Pressure error from the target specified in the Accesstuner calibration in percentage and then apply a relevant compensation.

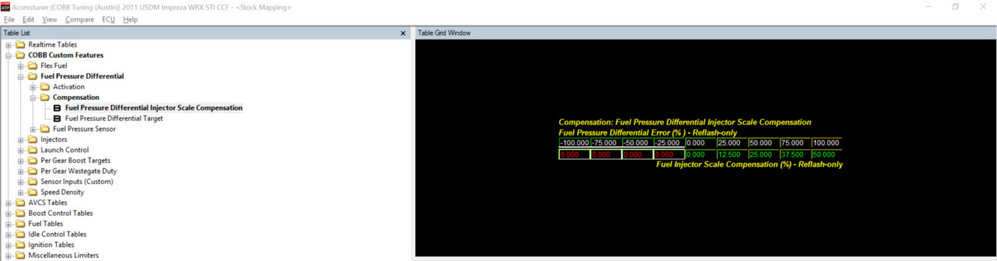

By default, the COBB Fuel Pressure Compensation features data based around Bernoulli's Principle. If the injector supplier can provide exact characterization, this default data can be updated based on the actual hardware in use. Alternately, the compensation can be configured to only respond to over-pressure (rich) or under-pressure (lean) errors. In practice, one may elect to only compensate during under-pressure situations to only protect against lean AFR and potential engine damage without adjusting things whenever minor over-pressure situations occur.

The active fuel pressure compensation itself can only "fix" a fuel pressure issue within the limits of the injectors; that is to say that injector duty cycle may still become a prevalent concern if the compensation is relied upon heavily.

The COBB implementation contains two main functionalities. The first is the ability to log both raw and differential fuel pressure; the second is the compensation, which is an optional component.

For the COBB Fuel Pressure Sensor Kit (Product Code: 315650), the calibration is 0.5-4.5v and 0-100psi. We recommend using 0.25v and 4.75v, respectively, as the low and high DTC thresholds.

Fuel Pressure Compensation Setup

- Determine if compensation is to be used in ACTIVE mode (logging and compensation both enabled) or PASSIVE mode (logging only enabled).

- Set Fuel Pressure Compensation mode. This is determined by the "Fuel Pressure Differential Feature" table.

- If ACTIVE mode is chosen, set "Fuel Pressure Differential Compensation Activation" thresholds. The default values allow for using the compensation under moderate RPM and boost (above 2500 RPM and above 0.0psi of Boost). The compensation can be made active under all conditions by setting both of these values to their maximum negative values (0 RPM and -15.0 psi).

- If ACTIVE mode is chosen, set current mechanical base (differential) fuel pressure target within "Fuel Pressure Differential Target" table. By default the software is set to 43.5psi (3 bar), as is the OEM vehicle. If an alternate base pressure is being used, update the value within the software as necessary.

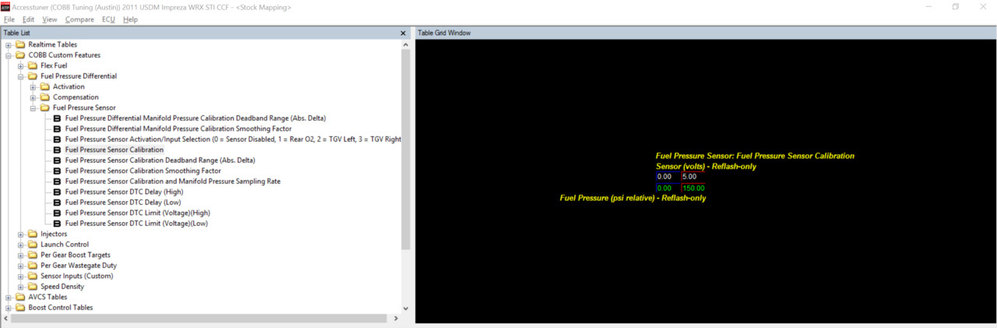

- Configure Fuel Pressure Sensor. Choose the input via "Fuel Pressure Sensor Activation/Selection" table, input the calibration via the "Fuel Pressure Sensor Calibration" table, and choose and input valid DTC voltage thresholds for the fuel pressure hardware in use via the "Fuel Pressure DTC Limit (Voltage)(High)/(Low)" tables.

- It is advisable to set the DTC thresholds a few tenths of a volt beyond the end of the valid calibration range and the end of the voltage range; for example, if the sensor uses 0.5v-4.5v for its sane range, setting the DTC limits to 0.25v and 4.75v should yield good results. A "C0BB3" DTC will be set for a Fuel Pressure Sensor Low Voltage error and "C0BB4" DTC for a Fuel Pressure Sensor High Voltage error. You may choose to adjust the Deadband Range, Sampling Rate and Smoothing Factor but the default values should work well for most sensors.

- Depending on the analog input chosen, you may need to remove DTC's for the OEM hardware to prevent the CEL from illuminating.

- If the C0BB3 or C0BB4 code is set, the Differential Fuel Pressure compensation is defaulted to zero (inactive). This functionality can be tested by quickly removing the fuel pressure sensor connector while the vehicle is running.

- It is advisable to set the DTC thresholds a few tenths of a volt beyond the end of the valid calibration range and the end of the voltage range; for example, if the sensor uses 0.5v-4.5v for its sane range, setting the DTC limits to 0.25v and 4.75v should yield good results. A "C0BB3" DTC will be set for a Fuel Pressure Sensor Low Voltage error and "C0BB4" DTC for a Fuel Pressure Sensor High Voltage error. You may choose to adjust the Deadband Range, Sampling Rate and Smoothing Factor but the default values should work well for most sensors.

- Please see "TGV Duplication Mode" section in the Subaru Custom Sensor Logging document if planning to utilize Custom Sensor Input option(s) while retaining TGV hardware.

- Sanity check the compensation's functionality by logging "Fuel Pressure Differential Actual" and if ACTIVE, "Fuel Pressure Differential Comp", which is the final active compensation based on fuel pressure. You can monitor "Fuel Injector Scale FINAL" to view the active changes being applied based on the fuel pressure compensation.

- WARNING! If the Fuel Pressure sensor hardware or associated wiring enters a failure state, it is possible to introduce either a direct short to the ECU's 5v power circuit or an overvoltage input to the ECU's 5v analog inputs. Either of these scenarios can potentially cause erroneous operation or ECU hardware damage.

Ex: Fuel Pressure Sensor calibration configured for AEM or SSI brand sensor that ranges from .5v-4.5v for measurements spanning 0psi-150psi.

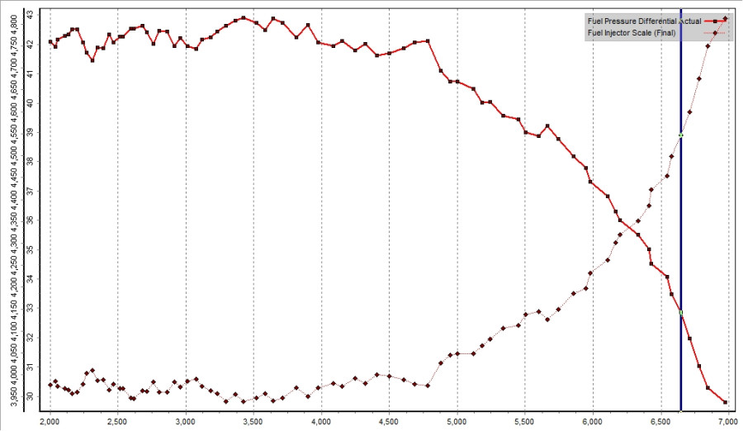

Ex: Differential Fuel Pressure compensation in action. In this case, target is the normal 43.5psi, but the fuel pump cannot keep up with demand. By around 6600 RPM, diff. fuel pressure is down to ~33psi. In response, Fuel Injector Scale has automatically risen to ~4500 to prevent fueling from an undesired leaning of air fuel ratio.

Ex: Modified differential fuel pressure compensation table that only compensates during under-pressure situations (positive fuel pressure error). Over-pressure (negative fuel pressure error) situations are ignored.

Related content

Copyright 2025 © COBB Tuning Products LLC. All Rights Reserved. | www.cobbtuning.com