Direct Injection Vehicles and Carbon Buildup

Table of Contents

Brief Overview: Direct Injection v Port Injection

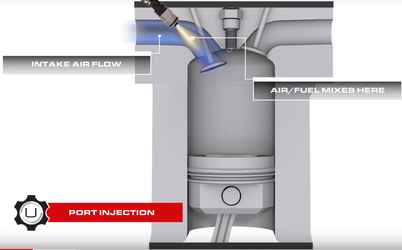

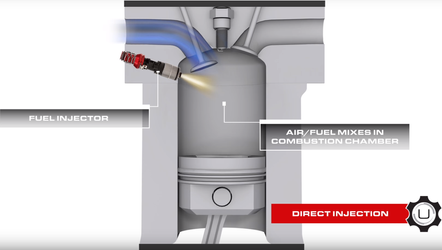

When looking at fuel injection systems there are two main injection methods for Multi-point Injection Systems: Direct Injection (DI) and Port Injection (PI). This refers to how fuel is delivered to each cylinder in your engine for combustion. With a port injection system, each cylinder has its fuel injected through its intake valves from a dedicated port injector. With Direct Injection Systems, fuel is injected directly into each cylinder after the intake valve.

.

In the last 10 years, we have started seeing a shift in OEM’s such as Subaru, Porsche, and Volkswagen move from the older industry standard Port Injection Systems to Direct Injection Systems with the added benefit of being able to get more power out of smaller high compression motors that require less fuel while also reducing emissions. There is also more control over when fuel is added to the cylinder since it doesn’t need the intake valve to be open to add fuel to a cylinder to optimize Air/Fuel Ratios.

Drawbacks and Caveats

That all sounds great right? While this technology is becoming more and more common in performance vehicles giving us a number of benefits, it also has several drawbacks. The injectors are more expensive than PI injectors, because of the materials that are designed to withstand the heat and pressure inside of a motor during the combustion cycle, and fuel components such as fuel lines, and pumps have to be able to hold and deliver fuel at higher pressures. The last drawback that is often overlooked is the added maintenance which is required for vehicles with Direct Injection, called carbon cleaning.

Since Direct Injection motors have the fuel being injected directly into the cylinder, fuel doesn’t flow over the vehicles valves. This means that deposits can settle on the back of the valves and over time will build up causing issues with the valves being able to seal properly, turbulent the air coming into the cylinder, in turn, causing issues with air/fuel ratios, rough idling, cold start issues, and misfires if the carbon buildup is bad enough. This is a service that requires you to remove the intake manifold to gain access to the intake valves for cleaning. Depending on the vehicle and driving conditions the car could require carbon cleaning every 30k-60k miles.

.

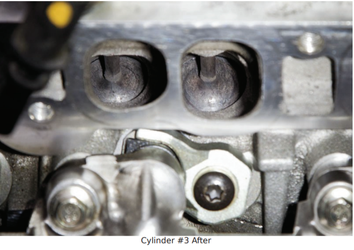

These pictures for example are from a Mazdaspeed3 we had with a little over 30,000 miles that was being used for testing. Prior to valve cleaning we had noticed on the dyno that this vehicle was unable to reach timing levels that we knew from previous experience were attainable on the vehicle, so it was losing power. Post valve cleaning we immediately saw the vehicle have a better idle and the vehicle was making less fueling corrections.

Troubleshooting For A Solution

There are two commonly used methods for cleaning carbon buildup: media blasting or doing a manual cleaning which requires several items such as GM Top Engine Cleaner, wire brushes, metal pics, and shop towels. The media blasting uses an air compressor with an attachment and broken up pieces of walnut shells to safely remove carbon buildup from the valves, polishing them so they are restored to their former glory. Using a media blasting method will add the additional cost of buying walnut media and a media blasting tool, but will also require a compressor and tank that is large enough where you won't have to constantly run it for the cleaning and it may still require some manual cleaning with a pick. Using a manual cleaning method is just as effective at cleaning the valves but may take more work and you have to be mindful to not damage the valves and seals with the pick.

Other than adding auxiliary/port fuel injection so fuel can reach the back of intake valves there isn't anything that will currently eliminate carbon build up and the need to clean it as part of your vehicles maintenance, however, there are ways to help minimize buildup such as keeping up with regular maintenance, such as spark plugs and injector cleaning to make sure the fuel injected into your cylinder are burned efficiently. You can also make modifications to your vehicle adding an Air Oil Separator, or a Catch Can system to help prevent blow-by from reaching your intake tract and making its way to your intake valves. These parts work in different ways to diffuse oil vapor from the air that goes through your vehicles PCV. The example on the left is a cutaway image of a Catch Can from our friends at 034Motorsports where the PCV air comes through a baffled inlet. On the right we have an example of the COBB Air Oil Separator which was developed in partnership with IAG Performance, the bottom of the AOS is shaped like a snail, redirecting positive crank pressure into a same swirl pattern produced by the 3 side ports. This swirl pattern causes the air to move along the inner walls of the separator to diffuse the oil and allows it to drain back to the crankcase.

Links

Extra Credit

COBB Tuning - COBB University Episode #7 - Fueling System

Suggested Tools for Carbon Cleaning

SONIC Tools - Mini hook set 4 pcs.

Harbor Freight - Gravity Feed Blaster Gun

Harbor Freight - 25.00 lb. Walnut Shell 24 Grit Fine Abrasive Media

Genuine GM Fluid 1052626 Upper Engine and Carburetor Cleaner - 13 oz. Aerosol

Parts

COBB Air Oil Separators for Subaru

034Motorsport Catch Cans for Volkswagen

Customer Support

Phone support available 9am to 6pm Monday-Thursday. 9am to 4pm Friday (CST)

866.922.3059

Related content

Copyright 2025 © COBB Tuning Products LLC. All Rights Reserved. | www.cobbtuning.com