771600, 771612 - Mazdaspeed3 Front Mount Intercooler Gen1 and Retrofit Kit

771600 – Mazdaspeed3 Front Mount Intercooler Gen1

Mazda3 MPS 2007 - 2009

Mazdaspeed Axela 2007 - 2009

Mazdaspeed3 2007 - 2009

Congratulations on your purchase of the COBB Tuning Mazdaspeed 3 Front Mounte Intercooler! The following instructions will assist you through the installation process. Please read them BEFORE beginning the install to familiarize yourself with the steps and tools needed. If you feel you cannot properly perform this installation, we HIGHLY recommend you take the vehicle to a qualified and experienced automotive technician.

IMPORTANT! Installing this kit will require custom tuning or utilizing an appropriate Stage Power Package map if you have a matching mechanical configuration. Please consult with COBB or an authorized ProTuner in your area if you have any questions!

Table of Contents

Parts List

- Charge Piping

- Lower Cold Side Charge Pipe

- Cold Side Mid Charge Pipe

- Throttle-body Cold Side Charge Pipe (Has BPV Flange)

- Upper Hot Side Charge Pipe (Has mounting bracket)

- Lower Hot Side Charge Pipe

- Intercooler Core Assembly

- 90 Degree Silicone Joint/Reducer

- 2.5” to 2.75” Straight Silicone Reducer

- (5) 2.5” Inner Diameter Straight Silicone

- (2) Intercooler Core Brackets

- (2 Parts) Power Steering Cooler Bracket

- Power Steering Line Brace

- (1) 2792N T-bolt Clamp

- (12)2793N T-bolt Clamps

- (1) 2794N T-bolt Clamp

- (4) Intercooler to Bracket Bolts

- (4) Intercooler to Bracket Bolt Flat Washers

- (4) Intercooler Bracket to Radiator Support Bolts

- (3) Power Steering Bracket Bolts

- (3) Power Steering Bracket Bolt Flat Washers

- (3) Power Steering Bracket Bolt Lock Washers

- Power Steering Brace Bolt

- (2) Power Steering Brace Flat Washers

- Power Steering Brace Lock Washer

- Power Steering Brace Nut

- Shift Weight

- (2) Shift Weight Buttonhead Bolts

- (2) Shift Weight Lock Washers

- “COBB” Logo Stencil

Tools Needed

- Phillips head screwdriver

- Flathead screwdriver

3/8" ratchet

3/8" 8mm socket

3/8" 10mm socket

3/8" 12mm socket

- 3/8" 5mm Hex Key or Hex Socket

- 3/16" Allen wrench of Allen Socket

3/8" 12" extension

3/8" 6" extension

- 10mm combination wrench

- 12mm combination wrench

- Torque Wrench

- Razor Knife

Before You Begin

We suggest checking with the dealer to see if your car may be a candidate for the Mazda recall on one or more of the engine mounts, or invest in some stiffer after market engine mounts before starting on the installation of the COBB FMIC. Excessive engine movement may cause a properly fitting kit to rub

Front Bumper Removal

- Park your car on a flat level area and jack up the front end so you can easily access the bottom side.

- Unhook the negative terminal on the battery.

- Start by removing the 8 Phillips head screws on top of the front bumper cover (two will be machine screws and 6 will be plastic fasteners)

- Moving on to the driver's side of the front bumper, remove the two plastic Phillips head fasteners that attach the fender liner to the front bumper and pull the fender liner back to remove the 8mm screw attaching the edge of the bumper to the fender, once done repeat on the passenger side.

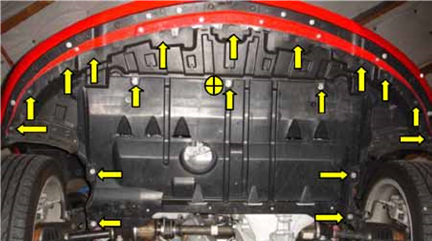

- Hopping underneath the car, completely remove the undertray by undoing the eleven 8mm screws, seven 10mm bolts and the one plastic fastener in the very middle (marked with an X).

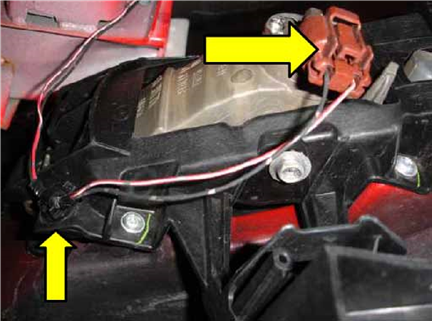

- With the front undertray removed, you will need to disconnect the fog light connectors on both sides and the plastic clip that retains the wire harness.

- You will also need to disconnect the ambient air temp sensor and the two plastic clips securing the wire harness to the bumper.

- At this point the bumper should be ready to be removed. Start by popping the rear edges of the bumper out of the retaining clips on the fender. There are also two tabs on each side behind the front grill that secure the bumper cover to the bumper beam. In order to release the clips you'll need to lift it up slightly while pulling the bumper cover off. It may help to have another person supporting the bumper while you left the tabs in order to prevent the bumper from falling on to the ground.

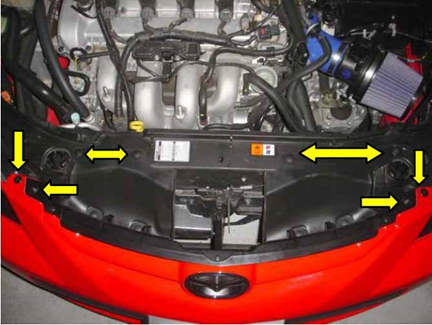

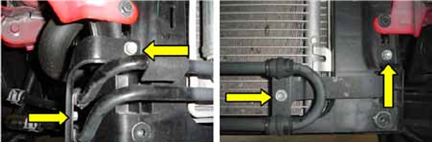

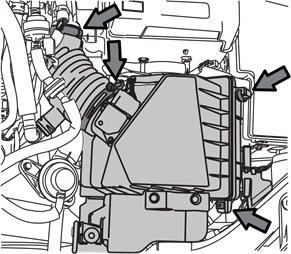

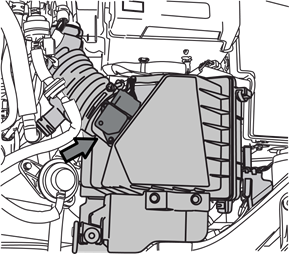

- With the front bumper cover removed you will need to make room for the intercooler and piping by removing left and right side plastic ducting. There are two plastic retainers and three 10mm bolts on the left side ducting as well as two 10mm bolts on the right side. The arrows will show the ducting to be removed not where the hardware is.

- It will also be a good time to remove all of the factory brackets that secure the power steering cooler lines. There are two 10mm bolts securing the left side and two 10mm bolts securing the right side.

Removal of the Factory Top Mounted Intercooler

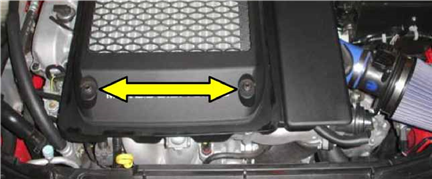

- It is now time to move back to the top of the car and remove the stock factory top mounted intercooler. Start by removing the two 10mm bolts that hold on the intercooler/engine cover. With the bolts removed, lift the front of the cover up and slide it back to release it from the retaining bracket on the rear of the cover.

- With the cover removed you can now remove the factory intercooler by removing the three 12mm nuts that secure the intercooler to the top of the motor. Set one of these aside as it will be reused on the upper intercooler pipe bracket. You will also need to loosen the 10mm hose clamp from the rubber hose on the turbo outlet and the 10mm hose clamp that secures the rubber hose to the cast intercooler outlet. Now using a pair of needle nose pliers remove the clamp on the vacuum line that goes to the top of the bypass valve, and the clamp that secures the bypass valve return hose. With the vacuum line and bypass valve hose removed you should be able to lift the factory intercooler up and out.

- With the factory intercooler out of the way you can now completely remove the rubber hose from the throttle body by loosening the 10mm hose clamp. It is also necessary to completely remove the bypass valve return hose from the turbo inlet tube by using a pair of needle nose pliers to loosen the factory clamp. If you are using the Cobb or another aftermarket intake system you should be able to access everything without removing the intake. If you still have the factory air box it will now need to be removed before going any further. (Refer to the instructions below for factory air box removal.)

Removal of the Stock Airbox

- Using a 10 mm socket, loosen the hose clamp that connects the accordion rubber hose to the intake box. Loosen the hose clamp that connects the accordion rubber hose to the turbo inlet. Unhook the 2 metal clips on the right side of the intake box.

- Unplug the Mass Air Flow (MAF) Harness from the MAF Sensor by pushing down on the tab and pulling away from you. Remove the two screws attaching the MAF Sensor to the MAF Housing using a Phillips head screw driver. Carefully remove the MAF Sensor from the housing and place it in a safe area. Remove the top of the intake box.

- To remove the lower section of the intake box, squeeze together the white retaining clip and pull up. Slide the rubber stop away from you. Remove the rubber retaining strap on the left side of the box by pulling up and to the left. Pull up on the box to pull it out of the two rubber plungers at the bottom of the box. Remove the accordion rubber hose from the turbo inlet.

Installation of Supplied Shift Weight

- Remove the factory shift weight using a 12mm socket or open ended wrench.

- Install the supplied shift weight by placing it on top of the lever arm and secure with the supplied 5mm button head screws and lock washers. This will allow for more clearance on the piping.

Intercooler Prep

If you want to add that special flare, you will want to take this opportunity to apply a COBB logo to your intercooler core using the supplied stencil. It is cut so that it is properly centered in the bumper skin opening if you apply it as shown in the picture below. The top of the vinyl is lined up with the top of the core and it is equally spaced in between the end-tanks. Use your own judgment in paint preparation and application.

Front Mount Intercooler Installation

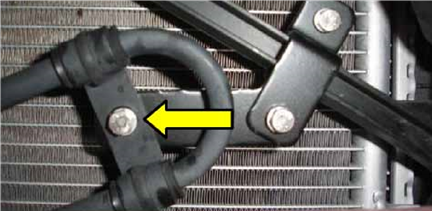

- Loosely install the COBB power steering cooler line relocation bracket around the plastic radiator core support brace as shown using the supplied bracket, two bolts, two flat washers and two lock washers.

- Using the COBB power steering cooler brace, attach the brace to the chassis on the passenger side bumper beam using the factory nut and the bracket on the power steering lines using a 10mm bolt, a washer on each side, and a lock washer between the nut and flat washer.

- Bring the far end of the power steering line up to the COBB bracket and loosely install it using the supplied 10mm bolt and washers. Leave everything loose until the intercooler core is mounted.

- Using a razor blade or similar cutting device, you will need to trim 1 - 3/4" from the end of the bypass valve return hose that goes to the turbo inlet tube.

Note: It may be a good idea to start by trimming less from the end of the hose and wait until all of the piping is installed until you can see exactly how much will need to be trimmed for a perfect fit. - With the bypass valve return hose trimmed you may now reinstall it on the turbo inlet tube but do not reinstall the clamps as the hose may need to be rotated and/or re-trimmed before final installation.

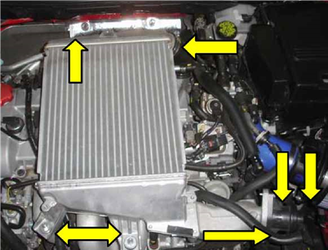

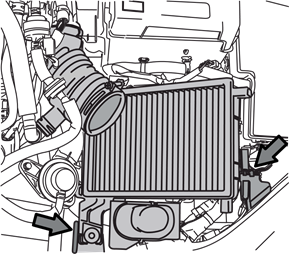

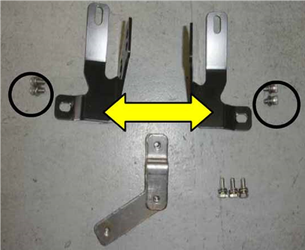

- It is now time to mount the COBB Front Mount Intercooler using the two supplied intercooler brackets, four 3/16" socket head hex bolts, four flat washers, and four 10mm bolts.

- Start by loosely mounting the intercooler support brackets to the intercooler using the four 3/16" socket head bolts and four washers as shown. (The front of the intercooler is facing up.)

- Now with the brackets loosely installed on the intercooler, lift it into place and bolt the brackets to the chassis using the 4 supplied 10mm bolts. Make sure that the power steering cooler lines are out of the way of the intercooler.

- Make sure that the intercooler has enough room in between the top of the core and the bottom of the bumper beam. You may need to tilt the bottom of the intercooler core back slightly to get as much room as possible when routing the piping. When you have determined the core is sitting properly, tighten the bolts that secure the bracket to the chassis first and then snug the 3/16” hex bolts. You may now also tighten all the bolts in the bracket that secure the power steering lines.

- Now that you have the intercooler securely mounted it is now time to install the cold side intercooler piping. We will start by installing the piping that runs from the throttle body to the right side of the intercooler. Start by removing the bypass valve from the factory intercooler by removing the 2 – 10mm bolts. Reinstall the bypass valve in the intercooler pipe that has the flange welded to it. Install the bypass valve reusing the factory 10mm bolts with the outlet facing in the same orientation as factory. Make sure that the rubber o-ring in the bottom of the bypass valve is in place and does not get pinched when reinstalling.

- Now place the straight reducer on the throttle body with the large end on the throttle body. Use the 2794N t-bolt clamp on the larger throttle body side and a 2794N on the smaller side. Tighten the 2794N with a 10mm deep socket in the orientation shown but leave the 2794N loose for now.

- Now slide the intercooler pipe with the bypass valve on it, into the silicone coupler and leave it loose. Angle the pipe slightly towards the transmission to get as much clearance as possible.

- The mid cold side pipe will connect to the end of the pipe that was just installed using a straight coupler and 2 – 2794N t-bolt clamps. The other end will connect to the lower cold pipe using another straight coupler and 2 more 2794N t-bolt clamps. The remaining end on the lower cold pipe will be attached to the right side end of the intercooler using a straight coupler and 2 – 2794N t-bolt clamps. It is best to slide the lower cold side pipe into the side of the intercooler core first, then the other end into the mid cold pipe. Install the clamps in the orientation shown but do not tighten any clamps yet until all of the piping is fully installed. Make sure it has as much clearance as possible between all power steering lines, chassis, and engine components. The piping will be close to the radiator support, so it is advised to add a piece of the rubber mastic tape supplied to this section to prevent any contact with the pipe.

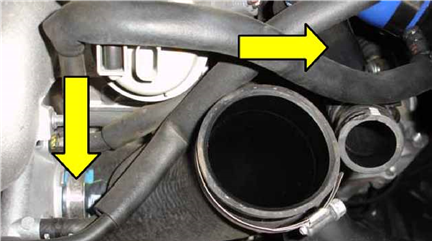

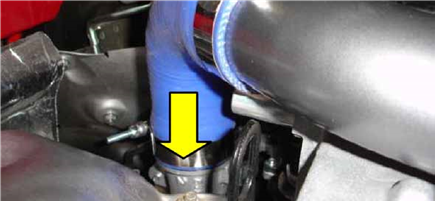

- Start on the hot side charge piping by taking the 2792N t-bolt clamp and placing it over the small end of the 90 degree silicone reducer. Slide the small end of the 90 degree silicone reducer onto the turbo outlet and leave it loose for now. The fit is pretty snug, so applying a small amount of lubricant to the inside of the silicone may ease installation. (Picture shows piping already installed)

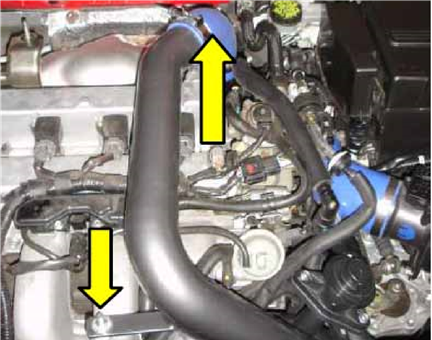

- Now place a 2794N t-bolt clamp on the large end of the 90 degree silicone reducer and take the pipe with the bracket welded to it and insert one end in the reducer and place the bracket on the stud located on the intake manifold. Re-use the nut that held the stock intercooler in place on the stud. Making sure that the tube is fully inserted into the reducer and that the orientation is correct, before you fully tighten the 12mm nut, as well as the 76 and 2792N t-bolt clamps

- Install the lower left side pipe by using a straight coupler and 2 – 2794N t-bolt clamps on the tube you just installed, and another straight coupler and 2 more 2794N t-bolt clamps on the left side of the intercooler outlet.

- With all the piping loosely installed, you may now tighten all the related t-bolt clamps. While tightening the clamps you will need to pay very close attention to a few key areas, as rotation of the pipes, and the amount the pipes are inserted into the couplers will drastically affect the overall fitment of the pipes.

***** It is the installers responsibility to make sure there is adequate clearance between the piping and anything the piping may come in contact with *****

Charge Pipe Installation Tips

- There are a couple of areas that it may be possible for the charge piping to contact. The first critical area is between the lower cold pipe and the radiator support. By playing with the angle of the intercooler core, rotation of the pipes and sliding the pipes in and out of the silicone you should be able to get at least 1/4” of clearance between the lower cold pipe and the radiator support. This along with the rubber mastic tape that you can apply to the pipe in that area, you should have more than enough room for the pipes to move without coming into contact with the radiator support. For additional clearance, you can slightly trim the radiator support in this area.

- The second critical area is the connection between the upper and lower hot side charge piping and the radiator fan. With proper pipe orientation you should also be able to get enough clearance in this area.

- If you haven’t done so already, now would be the time to reconnect the bypass valve hose and vacuum line and all related clamps. Also take time to re-check all your t-bolt clamps to make sure everything is secure. One last thing to check is to spin the fan blades by hand to be sure that nothing is coming in contact with the fan blades.

Front Bumper Re-Installation

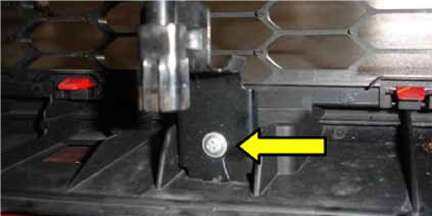

- Before you reinstall the bumper there are a couple of slight modifications that may need to be performed. The first step is that you may have to remove the ambient air temp sensor (AATS) from the inside of the front bumper by removing the phillips head screw that holds the bracket in place.

- With the AATS removed you will need to remove the sensor from the bracket by using a pair of needle nose pliers to squeeze the plastic clip. You will now need to remove the plastic clip from the AATS connector as shown by inserting a small flat head screwdriver in between the connector and the clip.

- Remount the AATS in the square hole in the left (driver) side intercooler bracket. If it is not a tight fit due to the plastic tab being older or breaking, you can secure it here with a few zip ties.

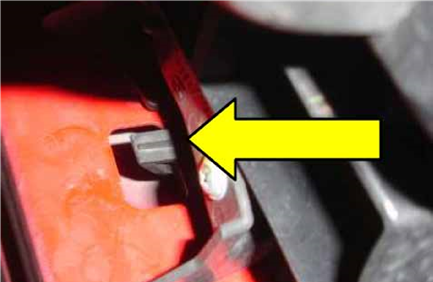

- Before installing the front bumper you may have to trim the two plastic areas used to retain the AATS wires with a razor blade or something similar. This may not be required on all cars.

- At this point the front bumper and undertray (along with everything else) can be reinstalled in the reverse order of removal double checking to make sure everything is tight.

- After flashing an appropriate map that supports the COBB FMIC it is now time to test drive. Upon returning from the test drive be sure to recheck all of the critical clearance areas as to be sure none of the piping has shifted from where it was when it was first installed. In our experience we have found some motors move around more than others due to the MAZDASPEED’s possibility of soft or broken motor mounts. If you find this to be the case we may suggest checking with your local dealer to see if your car may be a candidate for the recall Mazda recall has had on two of the mounts, or invest in some stiffer after market engine mounts.

- Go out and enjoy!

CARB Sticker Installation (On CARB Certified Applications)

This product is covered under multiple CARB EO letters. For additional information on CARB EO options for your Mazda, check out our page CARB EO numbers for COBB Mazda Products

Install the supplied CARB sticker on an easily viewable space that won't be susceptible to large amounts of heat. We recommend on the radiator core support, or the underside of the hood.

Links

COBB Product Install Instructions for Mazda Vehicles

Main Installation Instruction Repository for Mazda Parts

Link to Mazda Map Notes to see what map you should be on given the parts you've added

COBB Customer Support Web Support and Tech Articles: COBB Tuning Customer Support Center Email: support@cobbtuning.com Phone support available 9am to 6pm Monday-Thursday. 9am to 4pm Friday (CST) 866.922.3059 return to www.cobbtuning.comContact Us:

Copyright 2024 © COBB Tuning Products LLC. All Rights Reserved. | www.cobbtuning.com

.jpg?version=1&modificationDate=1520356957488&cacheVersion=1&api=v2&width=400&height=400)