- 2020-2021 Macan GTS

- 2020-2021 Macan Turbo

- 2019-2021 Macan S

Despite slightly different engine configurations, the 95B.2 Macan vehicles all use the same ECU and same general control strategy.

- Macan S

- 3.0 Liter V6 with a single twin scroll turbo mounted to the top of the motor between the cylinder heads, also called a "Hot Vee" configuration for channeling the heat of the exhaust into the center of the v portion of the block.

- Macan GTS & Turbo

- 2.9 Liter V6 with twin turbos. Also both centrally located between the cylinder heads at the top of the motor.

- These two vehicles are mechanically identical. The factory difference in power rating is entirely from the calibration.

Factory Calibrations

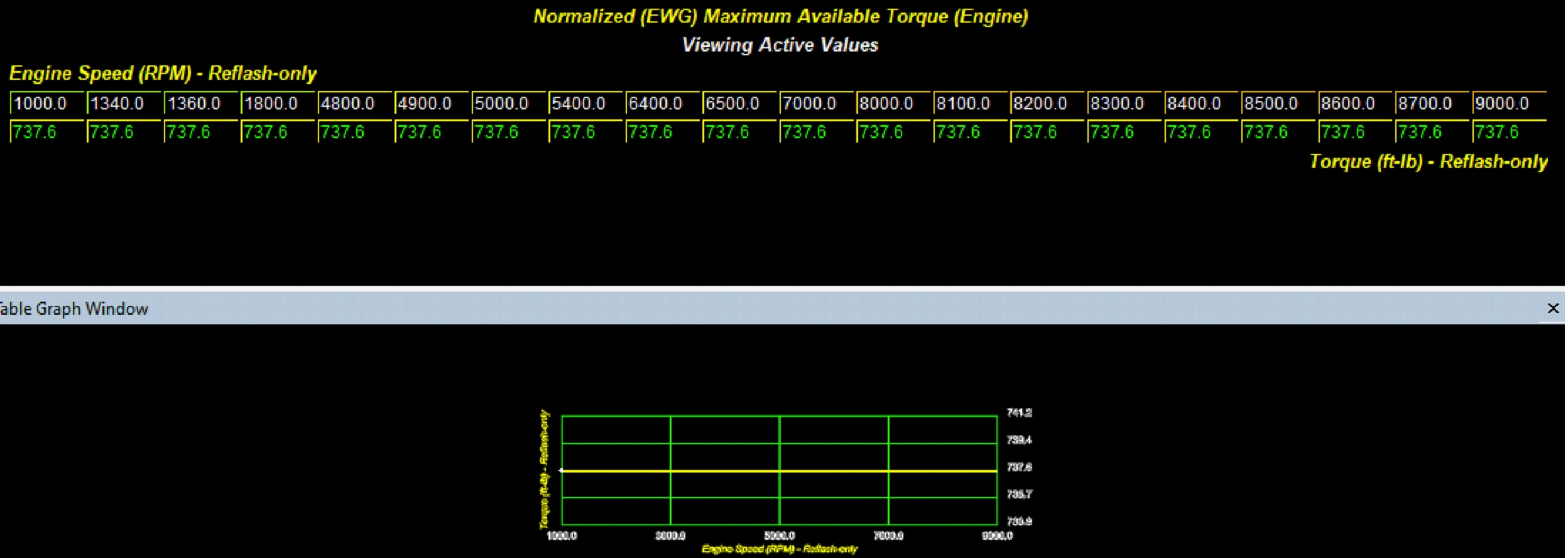

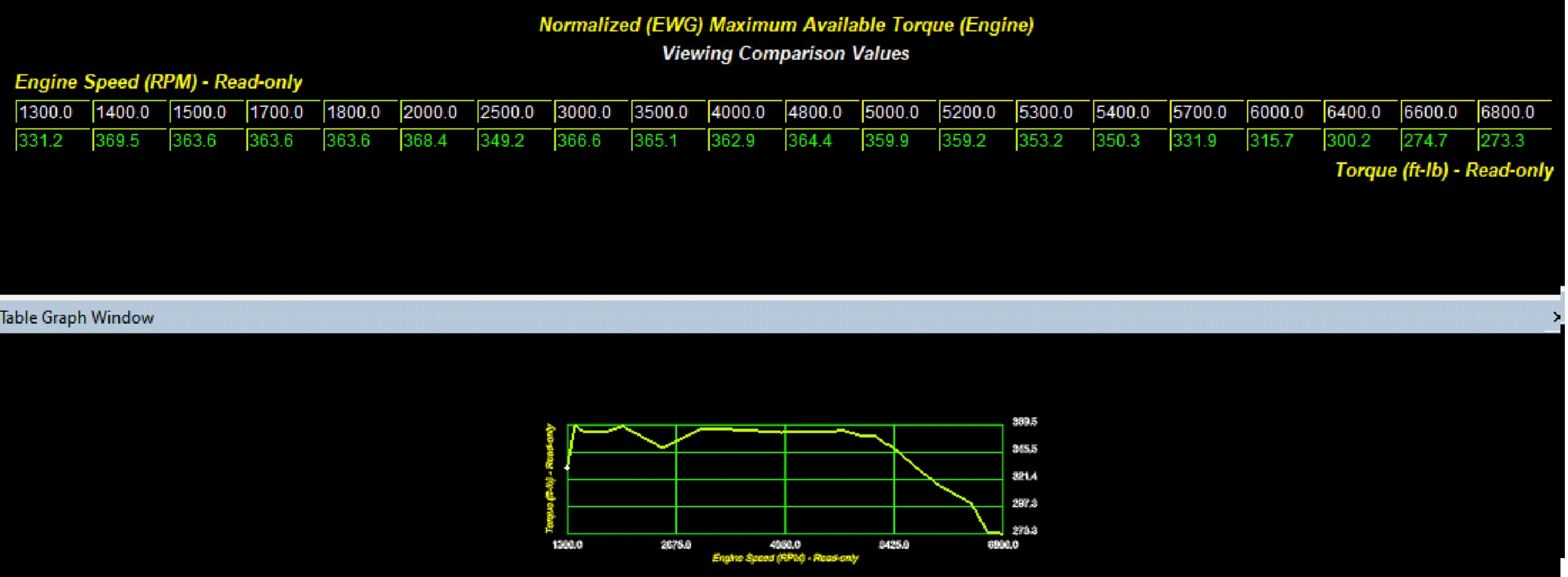

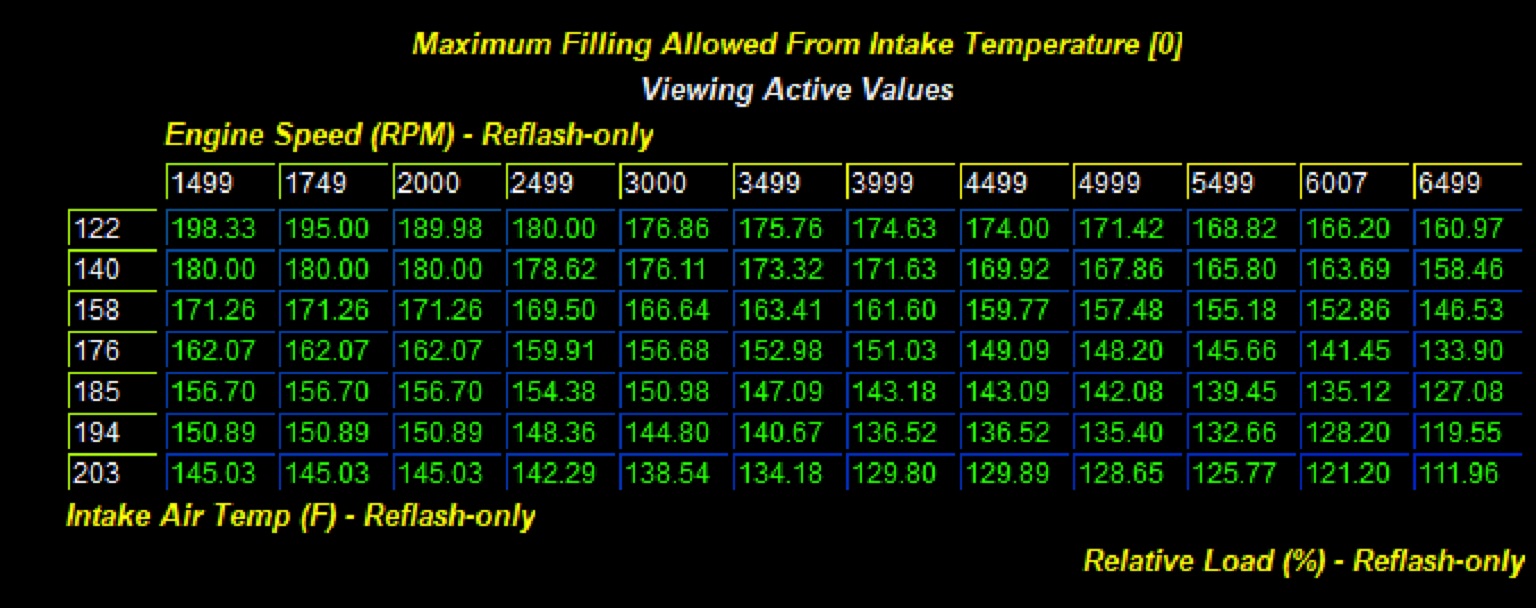

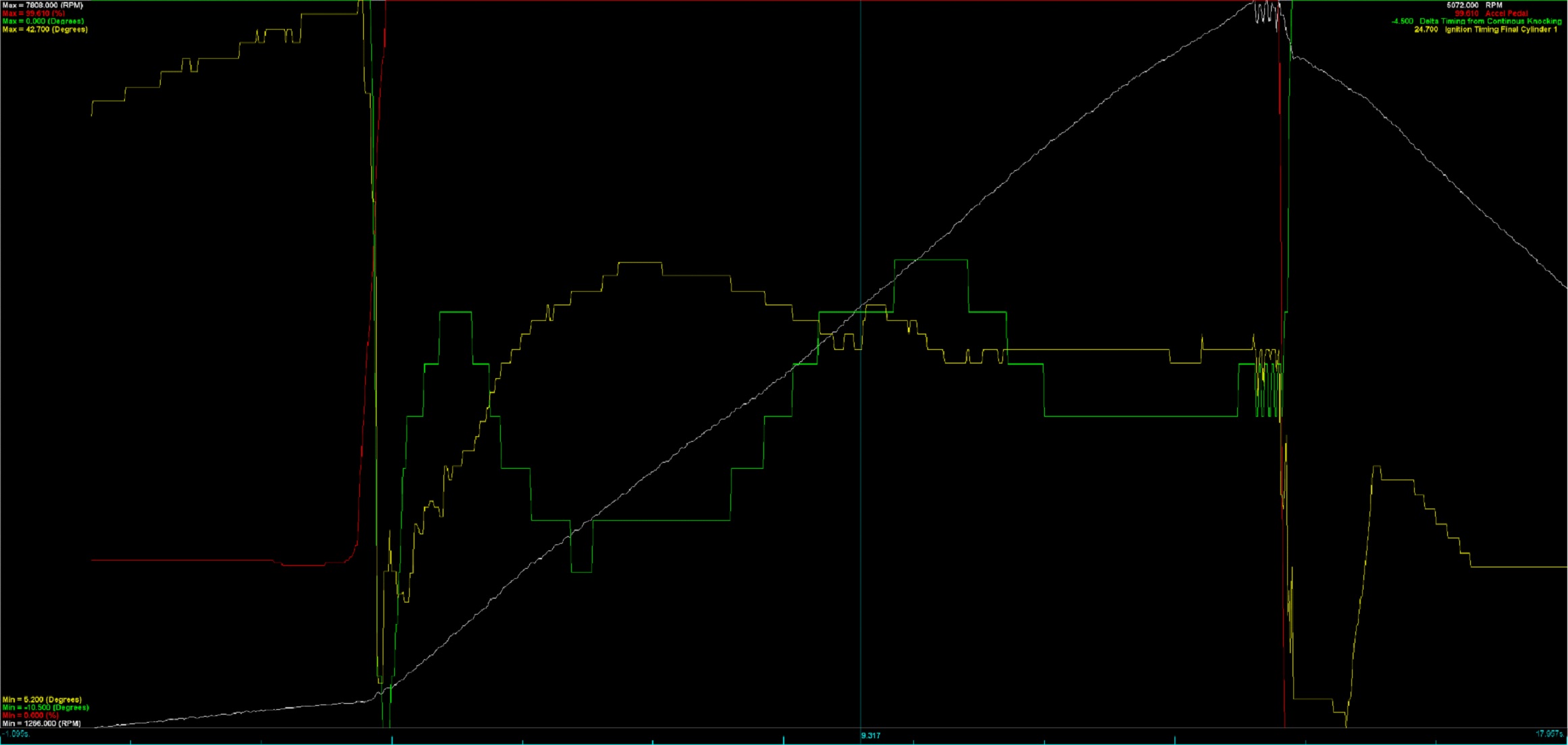

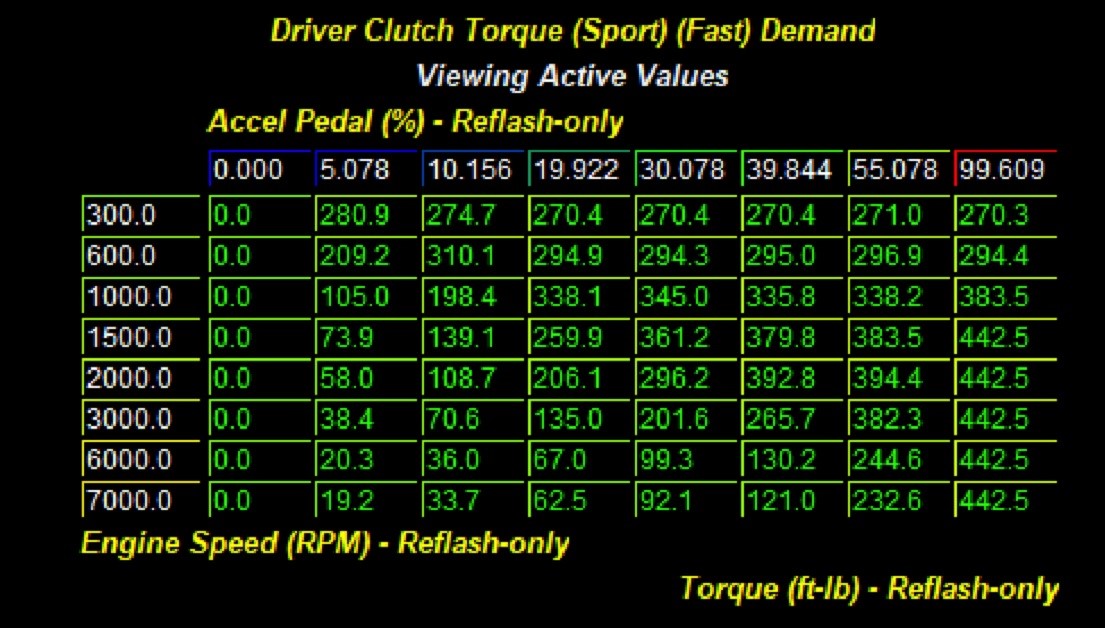

The plot below shows the stock curves from all three Macan models. The 3.0l motor found in the S (shown in green) is lower by comparison, however the turbocharger spools up more quickly. These cars make torque very rapidly, but aren't as efficient at high RPM. As such any attempts to increase power and hold out boost at higher RPM will typically just generate additional heat without increasing power.

In comparison, the GTS (Red) and Turbo (Blue) can move significantly more air at high rpm and will overall make more power. This additional airflow however results in a slightly later spool up compared to the S. As you can see by the relatively similar lines below 5000RPM, the calibration difference between the GTS and Turbo is a simple calibration change resulting in additional power at high RPM.

Calibration Results

Keep in mind tha the best and fastest way to evaluate your own calibration strategy is going to be to look at the COBB OTS maps as a starting point.

Macan S 95B.2 Map Notes

The ECU as a System

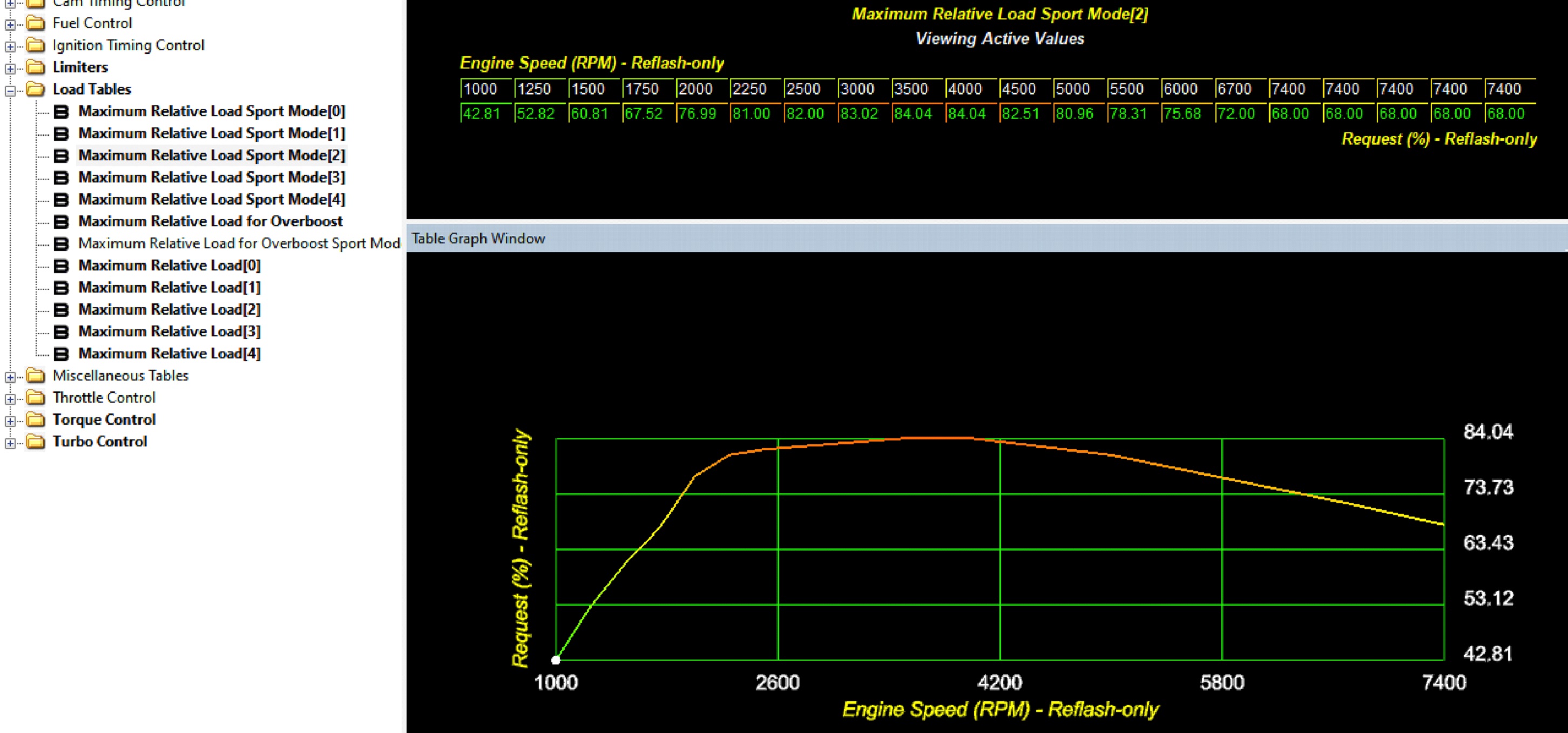

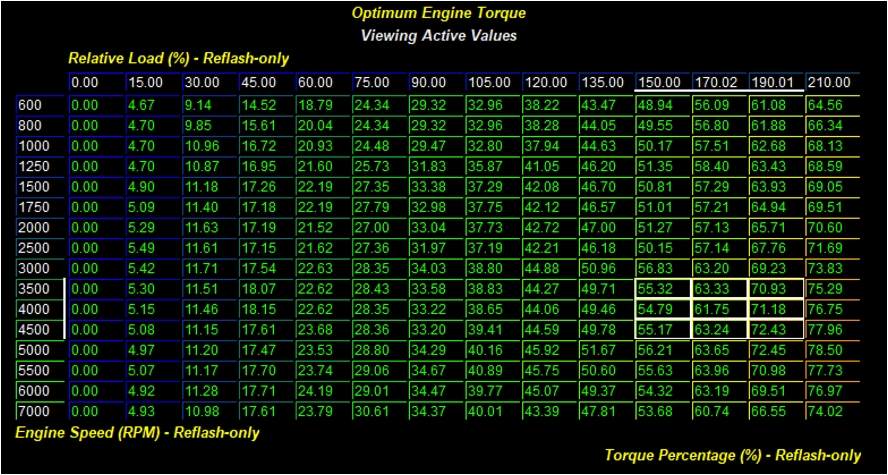

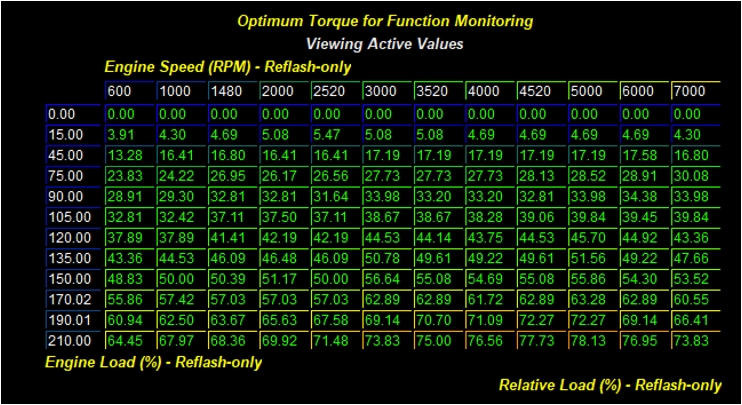

Porsche calibrations, regardless of ECU variants will require torque limits and targets to be adjusted (typically raised) to meat your goals. At the end of the day being able to adjust those tables and have everything work in concert is your goal. Within the range of Porsche vehicles there are a variety of tuning strategies which make achieving this goal a different process. This tends to mean that if you are an expert with 991.2 turbo 911 cars, everything will look somewhat familiar, but you'll still face a small learning curve in terms of exactly which tables require changing.

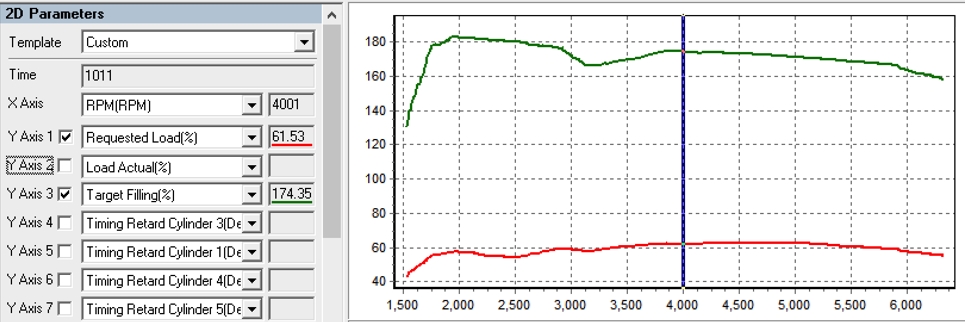

These ECUs have very well modeled tables looking for a fairly consistent level of vehicle operation. This means that in order to produce a finished calibration, you'll need to make a large range of changes. It's not possible to only change one parameter at a time and expect to make sustainable power. As an example, if you are working to optimize factory ignition timing or fuel, you will not see an increase of power in the presence of the factory torque limits and targets. In order to make power and tune the car the best way to start is to push the limits out of the way (but to a safe limit) in order to keep the vehicles behavior and targets consistent with the power you're targeting for your powertrain and fuel.

In order to preserve the balance of driveability and speed that the factory clearly worked so hard to achieve, it's recommended to minimize the table changes you do make. This seems counter intuitive when we just told you that you need to adjust more tables than you think, but if there is a change you feel may not be important or related to the desired behavior of the vehicle we recommend returning it to stock. This makes sure that the character of the vehicle can be preserved, and any undesireable effects from the complex interrelation between tables doesn't cause any issues.

.jpg?version=1&modificationDate=1657825063849&cacheVersion=1&api=v2&width=535&height=254)