Maintenance/Common Issues Reference Sheet

Applicable Vehicles :

WM 2007-2011 335i

WM 2007-2011 335xi

WM 2010-2013 335is

WM 2008-2011 135i

WM 2008-2010 535i

WM 2008-2010 535xi

WM 2009-2010 X6 xDrive35i

WM 2009-2014 Z4 sDrive35i

WM 2011-2014 Z4 sDrive35is

WM 2010 Z4 xDrive35is

WM 2010 X5 xDrive35i

WM 2011-2012 BMW 1M

USDM 2011 X5 sDrive35i

USDM 2011 X6

Maintenance and what to expect:

It is recommended to be aggressive with all factory recommended maintenance intervals mentioned in your owners manual. This is even more important when your asking for higher performance levels out of the vehicle.

If the vehicle is exhibiting random or constant misfiring check the following: fuel pump and injectors (early production cars), condition of the spark plugs, and carbon buildup on backs of valves.

Carbon cleaning is needed as early as 25K miles. All cases are different in terms of severity of the buildup and this situation is increasingly detrimental to performance. Needs physical inspection to be sure of the degree of buildup which includes removal of the intake manifold.

Example of dirty carbon coated intake valves vs. just cleaned. Recommended to use the walnut blasting method but other chemical and mechanical scraping methods also work but will cost more labor. Dealerships charge upwards of $1000 for this carbon removal service so shop around.

Earlier years 2007-2008 HPFPs are common to fail as well as both turbos. BMW USA has traditionally replaced these under warranty as it's well documented with TSBs.

Charge pipes more common on N55 to blow off of the throttle body at ALL performance levels. Simple replacement with a COBB charge pipe fixes this. Be sure to purchase a new OEM O-ring from your local dealership as it is not supplied with our charge pipes.

OEM air oil separators clog and build up pressure over time causing valve covers to leak.

Thermostats on N54 are electronic and prone to failures.

DTC P20FF Fuel Pump Plausibility code - Common but does not mean there is an issue with our OTS maps. Happens with stock BMW ROM programming. Existing BMW coding issue that has never been resolved.

These are the big reoccurring things that we notice with BMWs. Other issues can exist on a case by case basis.

Common Issues (all cars):

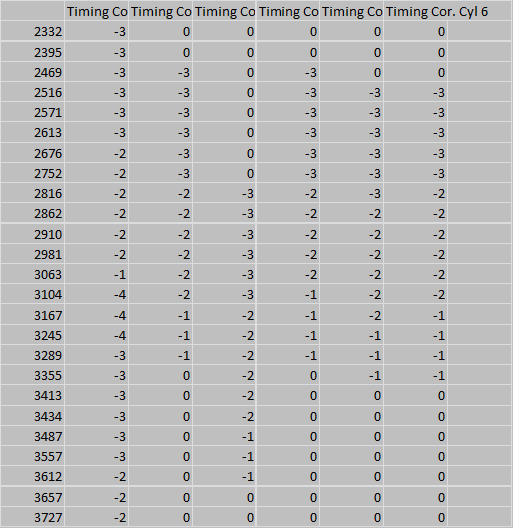

Incremental cylinder timing corrections that keep appearing and don't go away. Appears under "Cyl(1-6) Timing Cor" monitors. Confirm basics such as correct OTS map and octane vs parts all line up.

When you see consistent timing corrections, -3 degrees or more on 3 or more consecutive cylinders, that is something to be more concerned with. BMW's use individual cylinder timing corrections to deal with active knock.

Here is a small data sample showing a lot of timing corrections across all cylinders that are consistent. Cylinder 1 shows a quick -4 correction which is not good. The tune, fuel, and or mechanical condition of this vehicle needs to be inspected.

Look for throttle closures on datalogs. How do I know if that is happening? Your looking for Load Requested to be equal to or less than Actual Load. If this is the other way around that will cause the ECU to close down the throttle plate and very likely will cause immediate knock events.

Misfiring codes that popup randomly especially under load.

Ignition Basics

The N54 motor is BMW’s first shot at a turbo charged gasoline direct injection engine. A direct injection motor injects gasoline directly in to the engine cylinder where as a traditional fuel injected motor injects gasoline in to the intake tract or cylinder port. Because gasoline is injected directly in to the cylinder, BMW has designed a specific spark plug to sit at a specific location relative to the injector to ensure proper ignition. The ECU creates this ignition by telling the coil pack when to deliver the high voltage charge to the spark plug. This design combined with BMW’s advanced ECU logic allows the car to precisely control fuel and spark in order to not only increase performance, but fuel mileage as well.

Common Issues

As many owners have found, this incredible power has come with a few downsides. The now infamous high pressure fuel pump and injector recalls have caused multiple N54 owners check-engine-light anxiety. The BMW Maintenance Schedule calls for the spark plugs to be replaced every 45,000 miles, but our experience shows that this maintenance interval should probably be closer to 25,000 miles. We have also seen the other part of this spark equation, the coil packs, fail on cars with low miles. So, in short, our internal testing and experience has shown that the ignition system requires more stringent maintenance in general, but especially on a modified car.

Early Detection

In the very beginning stages of this inevitable issue, indications will only show themselves when the car is pushed hard due to tuning combined with more aggressive driving. In many cases, the misfires caused by the combination of tuning, bolt-on parts and aggressive driving style will throw check engine codes, however, under some loads, the misfire may only be felt by the driver without a resulting trouble code. The intricate BMW ECU logic is able to measure the variance in the expected acceleration of the crank to determine if the car is misfiring. When the coil pack is trying to create the spark, it is fighting against pressure in the cylinder and spark plug condition. Cylinder pressure is closely related to engine torque, so when torque is increased at higher RPM, the coil pack must recharge between sparks more quickly while still providing ample voltage to the plug. If the plug is worn out, it requires a higher voltage to jump the gap and could cause a misfire. If the coil pack is worn, it would not be able to recharge quickly enough to provide the required voltage to the plug. Therefore, this is why many users only see misfire codes with a tuned car and not on stock mapping. As the coils and plugs continue to degrade, even the stock mapping will have misfire issues.

Diagnosis and Repair

Despite the ominous engine covers and BMW mystique, changing the spark plugs and coil packs is an easy process. When you first have misfire issues, the first step is to change the spark plugs. If misfire codes still persist, you can easily diagnose coil packs by swapping them to an alternate cylinder. If the misfire code follows the coil pack, then the coil pack should be replaced. In the unusual case where the misfire remains in the same cylinder, you could potentially have an injector issue or other mechanical ailment.

The first step to removing the plugs is to get the right tools. You will need:

8mm Driver

5mm Hex Driver

BMW Specific Plug Tool

Torque Wrench

1. Remove the covers on the left and right sides of the cabin filter tray near the window. There is a clip on each side of these covers. On the passenger side, you will also need to un-clip the wire harness and disconnect the connector.

2. Remove the 8 8mm bolts holding the cabin filter to the cowl. Undo the rubber clips on each side as well. You can now remove the filter and set this assembly aside.

3. Un-clip the wiring harness holder attached to the underside of the cabin filter tray.

4. You should now be able to remove the cabin filter cowl with a little wiggling.

5. Remove the 4 5mm hex bolts from the engine cover: 2 in the front, and 2 in the back.

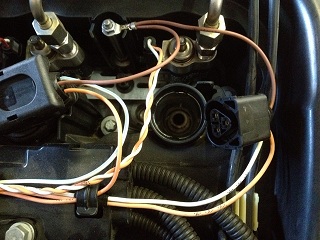

6. Once you remove the engine cover, you’ll see the coil packs and wiring harness.

7. The top cover of the coilpack will un-clip. When you lift this clip, it will push out the coilpack connector. Now put any driver through the hole in the coilpack clip and lift it straight up to remove the coilpack.

8. Using the BMW spark plug tool, you can now remove the spark plug and swap them out (.028" gap). The specified torque for replacement is 23 NM or 17 lb-ft.

9. Assembly is in the reverse order, but there are a few things to keep in mind when reassembling:

Be careful not to squish the foam on the rear section (nearest the windshield) of the engine cover.

Take your time lining up the clip for the wiring harness holder. It will gently snap in place.

The finely threaded bolts on the cabin filter go towards the outside of the vehicle.

Over-tightening the bolts that hold the cabin filter in place can cause the plastic to strip, so be careful!

With fresh spark plugs and potentially new coil packs, your car should be running great!

Definitions:

|

|

|---|