E1120G - COBB Subaru 20g Turbocharger

Congratulations on your purchase of the COBB Tuning 20g Turbocharger! The following instructions will assist you through the installation process. Please read them BEFORE beginning the install to familiarize yourself with the steps and tools needed. If you feel you cannot properly perform this installation, we HIGHLY recommend you take the vehicle to a qualified and experienced automotive technician.

IMPORTANT! Installing this kit will require custom tuning or utilizing an appropriate Stage Power Package map if you have a matching mechanical configuration. Please consult with COBB or an authorized ProTuner in your area if you have any questions!

| Warning |

|---|

If your vehicle had a previous turbo or other engine failure there may still be metal debris in the oiling system. It's important to ensure the oiling system is clean and metal-free so make sure to replace items that need to be (like oil coolers) and properly flush and clean out the rest of the systems. |

Table of Contents

| Table of Contents |

|---|

Parts List

- COBB 20G Turbocharger

- Turbo to Uppipe Gasket

- Turbo to Downpipe Gasket

- (2) m8x1.25 bolts

- (2) WRX Top Mount Intercooler Spacers

- (3) Mounting flange studs

- (3) Mounting flange nuts

- Hose and clamps for wastegate to compressor outlet

Tools Needed

Hand Tools

Misc.

Wrenches

Prep

- Park your car in a flat level area

- Give your car time to cool down.

- If your car is older or you live in a rusty climate, take some time to spray some penetrating oil on the exhaust bolts the night before and to check for any damage that may need to be repaired while you're doing this job.

Intake Removal

| Insert excerpt | ||||||

|---|---|---|---|---|---|---|

|

Top Mount Removal

| Insert excerpt | ||||||

|---|---|---|---|---|---|---|

|

Downpipe Removal

| Insert excerpt | ||||||

|---|---|---|---|---|---|---|

|

Intake Manifold Removal

| Insert excerpt | ||||||

|---|---|---|---|---|---|---|

|

Turbo Removal

- While working on the turbo, watch out for this bracket that had the wiring harness attached to it. It's really sharp.

- Make sure the cooling line leading from the top of the turbo to the expansion tank was removed.

- Undo the 10mm holding the oil line to the side of the turbocharger.

- Remove the banjo bolt on the top of the turbo using your 14mm. Make sure not to let the crush washers from the banjo bolt fall into the engine if you didn't block the intake ports!

- Undo the lower coolant line using a pair of pliers. It's the line going over to the passenger's side with the metal shielding on it. Not the one at the bottom of the picture.

- Slide the oil return hose clamp down and off the fitting. It's pretty difficult to remove the hose from the turbo but it should pop off easily when going to actually pull out the turbo itself.

- Remove the vacuum lines from the compressor housing and wastegate actuator, making sure to mark them so you know which goes where upon reinstall.

- Undo the three lower bolt in this picture at the rear of the turbo using your 14mm.

- On the passenger's side of the turbo remove the remaining two bolts holding the turbocharger in place.

- Carefully remove your antiquated power-adder from the car.

- Make sure to remove the old uppipe gasket from the uppipe.

COBB 20g Installation

- Double check that the cooling fittings are tightened on the new turbo using your 17mm. Be careful not to overtighten,

- Double check the oil drain line with your 10mm. Be careful not to overtighten,

- Remove the banjo bolt and the two crush washers for installation later.

- Install the provided studs short thread end first into the bottom three holes. Use anti-seize on the threads to ensure easy removal later on.

- Add the new gasket onto the uppipe.

- Lower the new turbo in place making sure to get the oil drain line onto the fitting. (It sometimes helps to move the clamp back to where it was when installed to the old turbo. This means you just need to push the line up to get it to seat on the turbo's drain fitting.

- From underneath or using long pliers up top, get the oil return line into place and clamped.

- Pop the lower coolant line on.

- Using the provided banjo bolt and crush washers, install the factory hard oil feed line. You should have one crush washer on either side of the fitting. Make sure the original crush washer isn't stuck to the banjo bolt as two crush washers stacked will leak!

| - Add the vacuum lines for the EBCS going to the compressor housing and the wastegate.

- At this point you can go ahead and start reinstalling the rest of the parts onto the car (The turbo inlet, Intake manifold assembly, as well as the downpipe and top mount intercooler)

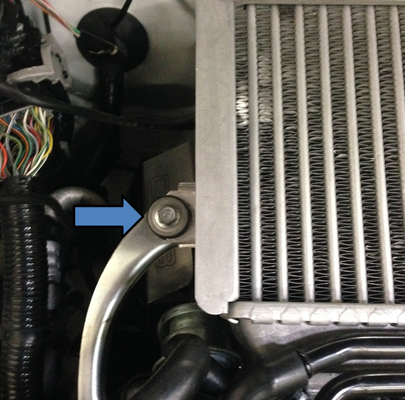

- With the later model cars where your intercooler sits more directly over the turbocharger (2015+) use the provided spacers and longer bolts underneath the mounting pad for the intercooler in order to gain the clearance needed to mount it over the turbo.

- With everything installed you can go ahead and add the remaining top coolant line from the turbo to the expansion tank.

Prime the Oiling and Cooling Systems

| Warning |

|---|

It is absolutely critical to ensure the cooling and oiling systems are filled and primed correctly in order to avoid damaging the internals of the turbocharger when the car is first started |

Perform an oil change, install a fresh oil filter and fill the engine with fresh oil.

Warning If an oil change is NOT performed prior to priming the oiling system any damage that occurs in the future will not be covered under warranty.

- With everything installed start filling up the radiator slowly, make sure to keep checking for leaks as you go and adjust hoses/tighten as needed.

- Once the radiator is filled up squeeze the hoses to try and get rid of as many air bubbles as possible, be careful as squeezing too hard too quickly can get coolant all over your engine bay.

- With as many of the air bubbles removed as you can go ahead and put the radiator cap back on. Keep in mind that the radiator cap and coolant reservoir cap typically look very similar, however the reservoir cap will be rated at a lower pressure so when in doubt refer to the stamped numbers that refer to the pressure rating in BAR.

- Now head up to the coolant reservoir and fill it up from there.

- In order to ensure the turbo doesn't fail prematurely it's critical to ensure that it gets not only coolant, but oil. In order to prime the oiling system start by disabling to fuel system. To do so either unplug the fuel pump at the top of the tank, or (if equipped) remove a fuel pump or fuel injector relay. How to do so will vary depending on your model carunplugging the crankshaft position sensor.

With the fuel system crank sensor disabled crank over the car for 5 seconds then let it sit for 30 seconds. Repeat this process 4 timesuntil your engine oil light is off. (It may be a good idea to have your car on a charger when doing so to avoid a dead battery)

Warning Failing to properly prime the oiling system can cause a failure and will NOT be covered under warranty.

- Take this chance to flash a map with 20g support to the car.

- With that done, you can re-enable your fuel system in anticipation of the first start.

- Fuel system enabled, key the ignition into the ON position. Check for leaks from the fuel system as you've had a bunch of stuff off the car.

- IT'S TIME!!! Give it a crank and see if it starts. Once it's running, check for leaks but don't let it get too hot yet before turning it off. Make sure to stop running the car if you see any fluids coming out, or hear any odd sounds. There will be a small amount of oil etc. that likely burns off of the turbo itself as it was oiled before being packaged.

- Now it's time to bleed the coolant. This is an important step and can get a little bit time consuming, however any pockets of air can cause issues with overheating or incorrect coolant temperature settings.

- While not necessary, a coolant bleeding funnel like this one can make things a whole lot easier as they come with fittings to mount directly to the cap and allow the system to bleed and fill itself at the same time.

Keep in mind that any coolant in the funnel will get just as hot as the rest of the coolant in the engine so use caution to avoid burns. - With the system full turn on the vehicle and crank up the heater all the way. By having the heater on the coolant can circulate through the heater core which will remove air bubbles from that portion of the system. Make sure to keep an eye on your coolant levels at the tank or in the funnel so that the car doesn't add any more bubbles into the system.

- Once the coolant stops bubbling you're all done with the bleeding! This can take a while (it took around 30 minutes on our car). While it's bleeding make sure to keep an eye on the coolant temperature in order to make sure your car isn't overheating and that the fans are cycling on and off properly.

While idling the radiator will got very hot quickly, be careful to avoid burns. - Place the plug securely down in the funnel and remove it from the car. Put remaining coolant back in the bottle.

- Reinstall the Coolant reservoir cap.

- Go out and enjoy!

Links

| Insert excerpt | ||||||

|---|---|---|---|---|---|---|

|