How Subaru's Factory Boost Control System Works

How Subaru's Factory Boost Control System Works

By: Christian

This document is intended to assist you with the understanding of how turbo boost pressure is controlled on an internally (or externally) wastegated turbocharger through the factory boost control system. This document will show how to properly set-up or calibrate your internally or externally wastegated turbocharger so that the boost pressure can be properly controlled by the stock boost control system. This document is broken down into four chapters; Hardware, Plumbing, Hardware Function, & Mechanical Calibration. Please read the following thoroughly before you attempt to tune your Subaru with the AccessTUNER software. In the AccessTUNER Professional or AccessTUNER Street software, Descriptions and Tuning Tips for most of the tables are provided and can be accessed by pressing the “F1” key while that table is highlighted in the Table List located on the left-hand side of the software.

We would like to go into further detail about the safeguards and advanced tuning features that are available through the AccessTUNER software. The boost control system uses a closed-loop targeting system that does everything it can to make the boost control system consistent. By employing this closed-loop boost control system the electronic control unit (ECU) can use its speed to bring down boost pressure in an over boost situation and raise the wastegate duty cycles for under boost situations. The stock boost control system is much faster than any human analysis and input; we highly suggest you use it to your advantage. In some vehicles, the boost control system can set higher boost targets up to certain miles per hour (MPH) or bring boost targets down after a set MPH. Some vehicles allow you to tune boost by the different gears you are operating the motor in. Most critical is the fact that the ECU (on DBW vehicles) forces the boost control system to shut down completely (so the vehicle runs mechanical boost pressure) if detonation events are continuing to occur. This bit of safeguard makes the factory boost control system far superior to any aftermarket boost control system, in our opinion. Once the stock boost control system is fully understood, you will find it easy to tune on an internally or externally wastegated turbos.

Chapter 1 – Hardware

Turbo - An exhaust-driven air compressor which consists of four basic sections or components. The compressor section consists of the compressor housing and the compressor wheel. This section acts as the inlet or intake for the turbo, compressing the intake charge and generating relative pressure (boost). Generally speaking, the inlet is always in a vacuum, sucking air in and the outlet is pressurized with the intake charge. Next is the center section which contains the bearings, shaft, and the oil and anti-freeze passageways; the compressor and turbine wheels are also attached to the shaft in this section. The third section is the turbine section which consists of the turbine wheel and turbine housing. This section also contains a machined by-pass for the wastegate valve to seat against. The last component of a turbocharger is the wastegate valve and wastegate actuator which controls the wastegate valve’s movement. We highly recommend that you use a turbocharger center section which is both oil and water cooled; turbocharger longevity is compromised when only oil is used to cool the turbocharger center housing.

Wastegate Actuator - A spring/diaphragm based mechanism which controls the movement of the wastegate valve. A turbo wastegate is normally closed, forced shut by a compressed spring inside the actuator canister. As pressure is applied to the nipple of the canister, the wastegate shaft moves away from the actuator, swinging open the wastegate valve.

Wastegate Solenoid Valve - An electromagnetic solenoid which controls the airflow from the wastegate actuator to the turbo inlet. This device is normally closed when no voltage is applied. When 12V direct current (DC) voltage is applied, by the drivers in the electronic control module (ECM), to the wastegate solenoid valve, it fully opens allowing air to pass through the device. A 0% Wastegate Duty Cycle (WGDC) setting will allow the solenoid to stay fully closed; which will force the turbo to run mechanical boost pressure. A 100% WGDC setting will force the solenoid to stay fully open; which will force the turbo to run maximum boost pressure.

Vacuum Lines - Rubberized or silicone tubes attached to various components in the engine assembly. For this article, we will be concerned with the six attachment points and the four sections of vacuum line plumbing and adapters which we will cover in Chapter 2.

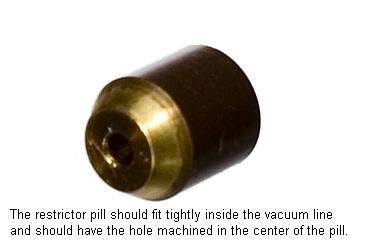

Restrictor Pill - A small pill made of brass which contains a precision-machined lengthwise hole in the center.

ECU - Also known as an ECM, PCM, EEC, EMS. The Engine Control Unit contains the processors, drivers, and logic which are calibrated to control the relative pressure (boost) via wastegate solenoid duty cycle.

Chapter 2 – Plumbing

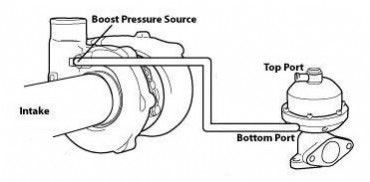

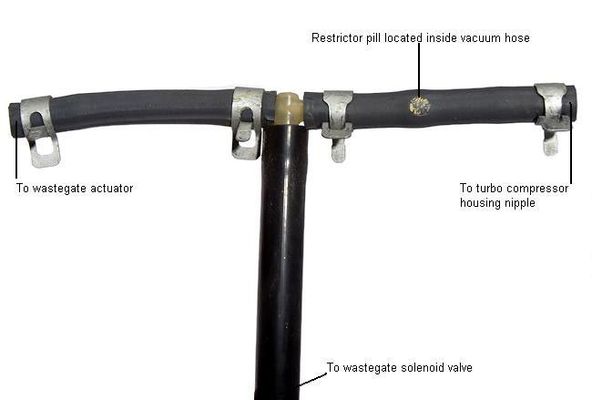

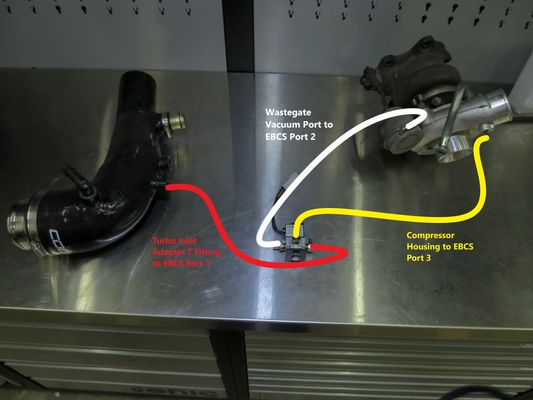

We will break down the plumbing of the factory boost control system into four sections of vacuum lines/adapters and six attachment points. Please look at the following picture where we have four basic lengths of vacuum lines and six attachment points labeled. Three of the lines are pressurized while the vehicle is under load, and one vacuum line, which goes to the turbo inlet tube, is under vacuum while the turbo sucks in air.

Line 1 plumbs the compressor housing to one end of the T-fitting. This line contains the brass restrictor pill.

Line 2 plumbs the wastegate actuator to the opposite end of the T-fitting.

Line 3 plumbs the middle of the T-fitting to the wastegate solenoid valve.

Line 4 plumbs the other side of the wastegate solenoid valve to the turbo-inlet pipe.

NOTE: You will notice your factory boost control system has more than four vacuum lines, this is because the factory uses couplers to connect the different size nipples to one section of line. For all intents and purposes you still only have four sections of lines.

Chapter 3 – Hardware Function

Turbo - The function of a turbo is to compress the intake charge, creating greater volumetric efficiency for the internal combustion motor.

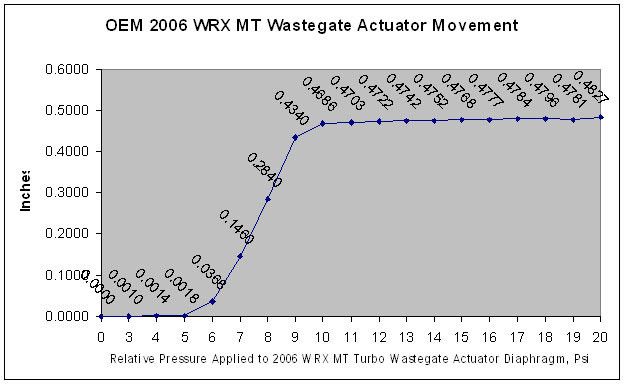

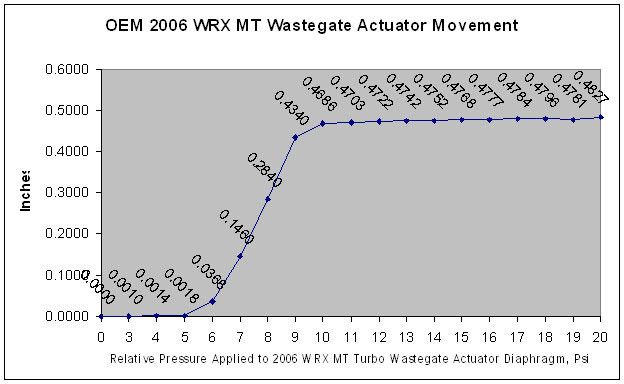

Wastegate Actuator & Wastegate Valve - A wastegate actuator's function is to control the wastegate valve. The wastegate valve manages the exhaust energy being directed into or by-passing the turbine housing. If the wastegate valve is fully closed, more exhaust energy is directed into the turbine housing causing the shaft speed of the turbocharger to increase and the relative pressure (boost) to increase, all within the efficiency range of the turbo. If the wastegate valve is opened the exhaust energy by-passes the turbine wheel and goes into the downpipe so that the turbo shaft speed decreases or remains constant. Opening the wastegate valve will generally lower relative pressure (boost) produced by the turbo. Below is a line graph demonstrating the rod movement of the wastegate actuator arm as pressure is applied to the canister nipple.

NOTE: The MORE boost you run, the LESS wastegate you need/use. So unless you want to run less boost pressure than stock and/or have un-tunable boost problems, we suggest that you do not port your wastegate by hand. We suggest you leave your wastegate, the area around it, the turbine housing, etc. alone and tune your boost curve through the proper means. You should only port your wastegate area once you have verified that you have a mechanical problem associated with the wastegate being too small.

Wastegate Solenoid Valve - The function of this device is to control the amount of air pressure being bled away from the wastegate actuator.

Restrictor Pill - This component limits the amount of pressurized air flowing from the turbo compressor housing. The restrictor pill restricts the airflow so the wastegate solenoid valve and wastegate actuator are not overdriven, which would force the wastegate valve to open prematurely.

Vacuum Lines - Vacuum lines plumb pressurized air to the proper components so the Subaru boost control system works properly.

ECU - This is the master device which controls the wastegate solenoid valve, the slave device, so that the targeted relative boost pressure is obtained.

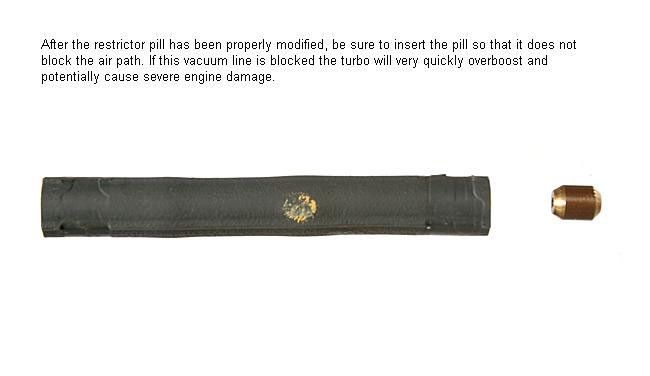

The factory boost control system bleeds pressure away from the wastegate actuator to the intake or turbo inlet pipe. With this device set at 0% wastegate duty cycle through the ECM calibration, all of the air pressure generated at the compressor housing will be applied to the wastegate actuator forcing the wastegate valve to fully open. When the wastegate actuator is fully open, the vehicle will run mechanical boost pressure which can be anything from 7-11psi on original equipment manufacturer (OEM) turbochargers. When this device is programmed to 100% wastegate duty cycle through the ECM calibration, all of the air pressure generated at the compressor housing will be allowed to by-pass to the wastegate actuator allowing the wastegate valve to close. The flow is limited by the size of the hole in the restrictor pill located in the first vacuum line attached to the turbo compressor housing. The wastegate valve will only close as much as it can (taking into consideration that the exhaust gas pressure between the exhaust port and the turbocharger is generally greater than the manifold pressure the turbo is generating) with the exhaust gas pressure pushing on the wastegate valve.

NOTE: If you run a turbocharger beyond its compressor efficiency range, it will turn into a flame thrower. When you push a turbo beyond what it is capable of doing, then the turbo may generate more boost pressure while over-heating the air charge to a point where it becomes dangerous and brings the engine closer to the detonation threshold.

Chapter 4 – Mechanical Calibration; Mechanical Tuning and Boost Control System Calibration Using the AccessTUNER Software

Mechanical Tuning

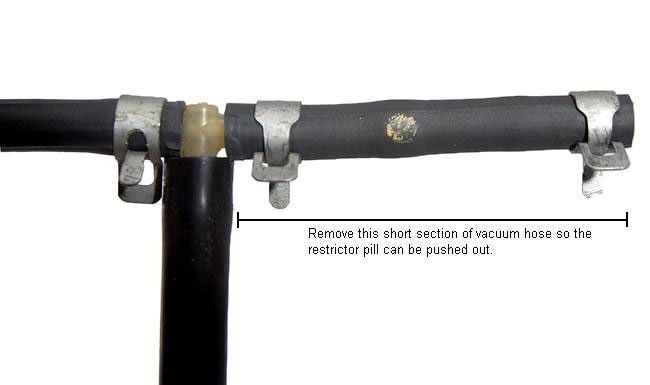

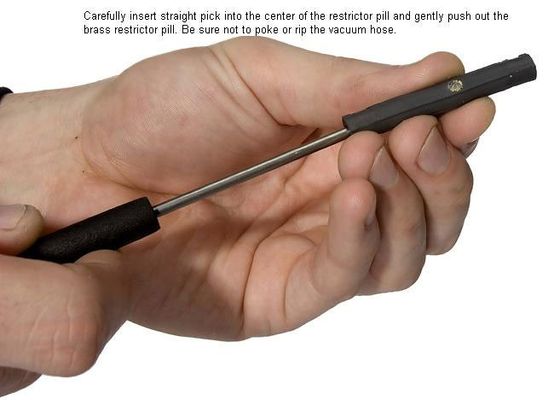

Changing the size of the center hole in the restrictor pill; the vacuum lines for the factory boost control system contain a small brass restrictor pill located in the short vacuum line coming off the turbo compressor housing. The middle of this restrictor pill has a lengthwise hole precisely machined to a certain specification so that it works with the factory wastegate actuator and the wastegate duty cycle settings in the stock ECU. The size of this center hole can be changed in order to mechanically assist boost control.

A smaller diameter hole in the center of the brass restrictor pill will have a higher tendency to create a boost spike in the system and require less wastegate duty cycle to run higher boost. The larger the diameter hole in the center of the restrictor pill, the less chance the boost control system will boost spike and the greater the wastegate duty cycle will need to run in order to produce higher boost. If you have a stock turbo and are running an AccessPORT map, you have no reason to modify your restrictor pill. If you have installed a new turbocharger and you are using the stock boost control system to tune boost, please verify that the vacuum line coming off the turbo compressor housing (prior to the T-fitting) contains a restrictor pill with a hole machined in the center of the pill.

The stock boost control system most commonly uses a restrictor pill with a center hole size of 0.040”-0.048” +/- 0.001” Below are some of the restrictor pill sizes we have commonly seen in the stock turbo Subarus.

For larger-than-stock turbochargers, or turbochargers with a stronger mechanical springs in the wastegate actuator, or turbochargers that have the wastegate actuator shortened to a higher pre-tension; we suggest you use a restrictor with a larger center hole, something along 0.040”-0.055” +/- 0.001”

For similar-to-stock-sized turbochargers, or turbochargers with a weaker mechanical spring in the wastegate actuator you, or turbos that have the wastegate actuator shortened as much as it can and you are still not hitting your target boost; we suggest you to use a restrictor with a smaller center hole, something along 0.025”-0.040” +/- 0.001”. Be very careful when using a restrictor with a center hole of this size, the boost control system will have a higher tendency to boost spike and you will need less wastegate duty cycle to run higher boost.

NOTE: The hole in the restrictor pill can always be machined to a larger diameter. Be sure to make very small increases in the diameter of the hole. If the center hole is machined too large you will not be able to hit your boost targets…even with 100% wastegate duty cycle

The location of the threads can be located at either end of the wastegate actuator rod, see the below picture where it demonstrates the threaded section is closest to the WG actuator diaphragm.

Pre-loading the wastegate actuator arm; adjustment of the wastegate actuator rod (if the rod length is not fixed and adjustments can be made) will allow proper calibration and some additional tuning as well All IHI turbochargers have a fixed wastegate actuator rod that cannot be adjusted, while all MHI turbochargers have an adjustable wastegate actuator rod. If the rod coming out of the wastegate actuator is shortened, it will pre-load the spring inside the wastegate actuator increasing the pressure level at which the actuator will allow the wastegate valve to open and the total boost pressure that the turbo can generate will increase (as long as the turbo is still within its efficiency range). This pre-load will also limit how far the wastegate valve can open. Pre-loading (shortening) the wastegate actuator rod too much CAN POTENTIALLY CREATE A MECHANICAL BOOST CREEP ISSUE THAT CANNOT BE TUNED OUT! If the wastegate actuator rod is lengthened, the actuator will decrease the load on the spring and decrease the pressure level at which the actuator will open and the total boost pressure the turbo can generate will decrease. If the wastegate actuator rod does not put enough pre-load on the wastegate valve, then you could see boost fluctuations of + or – 2psi even when the wastegate solenoid duty cycles are constant. If you have a stock turbocharger then you should not have to adjust the wastegate rod length.

NOTE: The larger diameter wastegate valve a turbo has, the more difficult it is to stabilize boost pressure as the valve initially opens. This is also true for greater exhaust gas back pressures created by a smaller A/R on the turbine housing.

Electronic Tuning Through ECU Calibration

The stock boost control system can be used to control boost on properly designed internal and external wastegate systems. If you have a turbocharger with a properly designed internal wastegate valve/actuator that has been properly calibrated using the correct size restrictor pill and wastegate pre-load you will be able to use the factory boost control solenoid.

NOTE: If you are tuning with an external wastegate, we have found that the Prodrive electronic boost control solenoid (EBCS) works perfectly with the stock compensatory wastegate calibrations (coolant, intake air temperature, etc.). This solenoid is a replacement for the stock EBCS and plugs in to the factory wiring harness. Tuning external wastegates with the factory boost control system (ECU) has worked very well as long as you use the COBB EBCS. Please refer to the below picture so you know how the plumbing of the COBB EBCS should be set-up. With the COBB EBCS you WILL NOT NEED TO USE ANY RESTRICTOR PILL!

The above diagram is only for internally wastegated turbos

You must be made aware that tuning the boost control system is the most difficult tuning you will perform on your Subaru. TUNING THE BOOST CONTROL SYSTEM IS ALSO GOING TO TAKE THE LONGEST TIME TO COMPLETE. Although, once you are finished tuning your boost control system you will be very appreciative of the complexity and capability of the OEM boost control system. The OEM boost control system is much faster than any human input so we highly suggest you start with lower wastegate duty cycles than you may need and work your way up from there. The boost curve and the stability of the boost curve must be established in order to allow you to properly tune all other tables from this point on. The MAF signal has a major influence on the ignition advance and fuel curve as this signal is the major component used by the ECU to calculate engine load (and in turn the fueling and ignition calculations).

The OEM Subaru boost control system employs a closed-loop, targeting system for tuning boost. You must first establish your boost targets in the Boost Targets table. The values in the Boost Targets table are in relative pressure, Bar or Psi. Running these boost targets is going to be the primary goal for the ECU. The ECU will start of with using the wastegate duty cycles established in the Wastegate Duty Cycles (Low & High) table(s). Some Subaru ECUs use a single Wastegate Duty Cycles table and some use two, Wastegate Duty Cycles Low and Wastegate Duty Cycles High. If your ECU uses the Low and High Wastegate Duty Cycles tables we suggest you set your Wastegate Duty Cycles Low table ~8% lower than the Wastegate Duty Cycles High table for the corresponding Throttle Position and RPM cells. The ECU will then use the Turbo Dynamics tables to adjust the wastegate solenoid duty cycle in order to achieve the dictated boost target. Other compensatory boost and wastegate tables are also used by the ECU to fine-tune boost for environmental changes, temperature, barometric pressure, etc. Although, these tables should not need to be modified when using the stock boost control solenoid. If the wastegate duty cycle values are too low, you will not achieve your target boost pressure. If the wastegate duty cycle values are too high, you will overshoot your boost targets and potentially damage the engine. We do not suggest you run a wastegate duty cycle of more than 95% to prevent overheating or lock-up of the wastegate solenoid, and to promote the longevity of the wastegate solenoid.

While tuning the boost control system you will want to datalog and/or view your RPM, Throttle Position, Wastegate Duty Cycle (WGDC), Relative Pressure, and Turbo Dynamics values so you can see what your ECU is actually doing to achieve its boost targets. The further your turbo dynamics value is from zero, negative or positive, the further away your engine is from achieving the dictated boost targets. Your boost targets are either too high or too low for that particular RPM and TPS point to achieve your boost target or your wastegate duty cycles are not close enough to where they need to be in order to achieve your boost targets. We suggest you tune so that your turbo dynamics value is a small positive number (8 or less for the DBC 2.0L vehicles, 100 or less for the DBW 2.5L vehicles) across the RPM range. We suggest you tune your boost control tables in this manner so that if you accidentally overload the engine (with additional passengers, going uphill, towing, flooring the car in higher gears at lower RPM, etc.) you have some protection against over-boosting.

If your datalogged turbo dynamics value is a negative value then your ECU will remove wastegate duty cycles to hit your boost targets because the engine is over-boosting; the pressure measured at your intake manifold is higher than what is dictated in the Boost Targets table for the given RPM and TPS values. If your boost is surging up and down or then your boost control is searching because it is grossly overshooting its target. If your datalog shows a negative value for turbo dynamics then the ECU will use the additional authority in the negative portion of the Turbo Dynamics tables to lower WGDC until the target boost is achieved.

If your datalogged turbo dynamics value is positive value then your ECU will add wastegate duty cycles to hit your boost targets because the engine is under-boosting; the pressure measured at your intake manifold is lower than what is dictated in the Boost Targets table for the given RPM and TPS values. If your boost is lower than what is dictated in your Boost Targets table then you will need to increase your WGDC for the given RPM and TPS values. If your datalog shows a positive value for turbo dynamics then the ECU will use the additional authority in the positive portion of the Turbo Dynamics tables to increase WGDC until the target boosts are achieved.

If you are increasing or holding wastegate duty cycles steady and boost is dropping then you have most likely reached the threshold of the mechanical efficiency of the turbo or your exhaust gas back pressure prior to the turbo is too high and is forcing the wastegate valve to open.

If you are having a small boost spike you may need to decrease the WGDC percentage a few hundred RPM prior to the over boosting event to allow the exhaust energy to be released past the turbine wheel.

NOTE: With porting a wastegate, you are trying and make the wastegate valve function potentially work better which means that your turbo is going to lower boost super fast when the wastegate door/valve opens or not run as much boost as it was engineered to. If you make your wastegate react quicker then boost will be very difficult to stabilize and reach peak #s at an earlier RPM. If you make the wastegate flow better, then the exhaust energy your turbo needs to make and maintain boost will have less opportunity to flow across the turbine wheel. Generally speaking, air/pressure/exhaust gases will always flow along the path of least resistance. Not bashing, just trying to give you a different perspective.

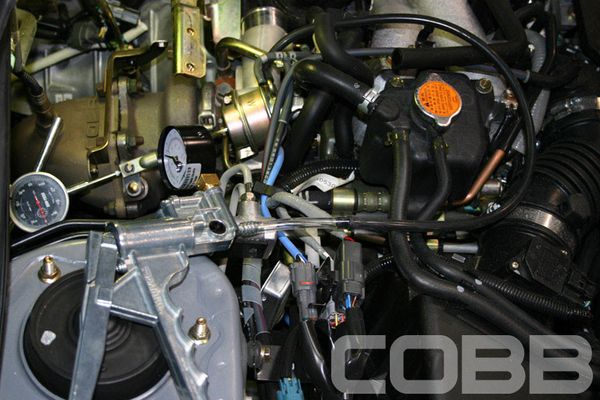

The remainder of this document is intended to demonstrate how to measure the wastegate pre-tension using a vacuum pump. Your WG actuator arm may need to be adjusted (shortened for more pre-tension and lengthened for less pre-tension) in order to achieve proper wastegate actuator movement. These measurements are all static measurements which do not take into account the effects that exhaust gas back pressure prior to the turbo (temperature, exhaust restrictions, etc.) will have on the movement of the wastegate valve.

The wastegate actuator is the bronze item with the “W” stamped on it in the above picture.

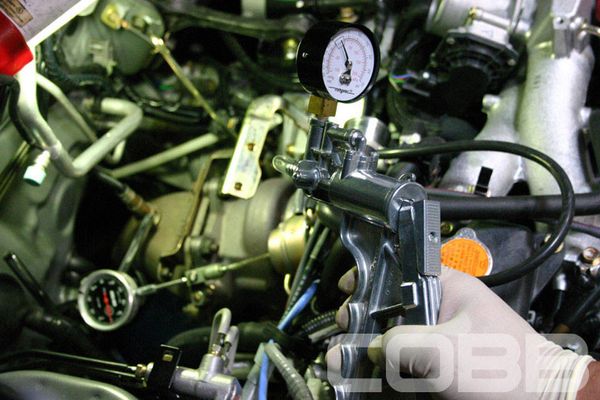

While the turbo installed on the vehicle, we suggest you expose the wastegate actuator rod so you can easily see the wastegate rod movement. Now you will need to remove the stock vacuum line attached to the WG actuator. Replace this line with the vacuum line from your vacuum/pressure pump.

A standard Mityvac™ vacuum/pressure pump can be used.

Plumb the vacuum line so it goes directly from the pump nozzle to the wastegate actuator nipple.

Be sure to set the pump so it is in pressure mode.

Now you can slowly pressurize the wastegate diaphragm; at some pressure level, you will see the wastegate rod move. Below is a graph of the WG rod movement for a 2006 WRX MT.

As you can see the WG rod begins to aggressively move at ~7psi. The pre-tension measurement for the WG actuator would be ~7psi, which means if you connected this actuator directly to a high-pressure source on the turbo compressor housing, your vehicle would produce around ~7psi of turbo boost (manifold) pressure.

To summarize, you have A few mechanical options for fine-tuning your boost control system.

Option 1 = Restrictor Pill Sizing, you can change the size of the restrictor pill employed in your system.

- A smaller restrictor pill will allow the system to generate greater boost pressures with the same or less WGDC, the trade-off is that the smaller restrictor pills can potentially induce boost spikes. These spikes can sometimes be tuned out by greatly lowering WGDC a few hundred RPM before the boost spike occurs.

- A larger restrictor pill will force the system to use more WGDC to achieve boost, which makes the conditions safer when you lose a section of vacuum line and the turbo goes into an overrun condition.

Option 2 = Wastegate Actuator Pre-Tensioning, you can change the amount of pre-tension on your WG actuator.

- Creating greater pre-tension will allow the system to generate greater boost pressures with the same or less WGDC, the trade-off is that the greater pre-tension can potentially create a phenomenon known as “boost creep” by not allowing enough exhaust gas energy to by-pass the turbine housing. On rare occasions, this boost creep condition may be tuned out by greatly lowering WGDC or setting the WGDC to zero at higher RPM.

- A larger restrictor pill will allow the system to use more WGDC to achieve boost, which makes the conditions safer when you lose a vacuum line and the turbo goes into an overrun condition.

Below are the various plumbing diagrams for the different types of electronic boost control systems. We will start with the more common, internally wastegated system in which the wastegate assembly is a design element of the turbocharger itself. Subaru employees a bleed-type boost control system (as opposed to an interrupt type) for controlling the internal wastegate systems. The logic present in the Subaru ECU is capable of tuning either internally or externally wastegated systems as long as they are properly set up. Please refer to the below diagrams to make sure your boost control system is mechanically set up in the proper manner.

The operating voltage for most EBC solenoids is usually 12 Volts, and the polarity is unimportant since the solenoid will require +12V power and the other wire is grounded by the ECU. When the solenoid is energized, ports 1 & 2 are connected allowing air to flow between them; when de-energized, ports 2 & 3 are connected allowing air to flow between them. Please take this port diagram into account when reading the below plumbing instructions.

NOTE: As a rule of thumb, you can generally only create turbo boost pressure which is twice your mechanical wastegate spring pressure through electronic wastegate manipulation. In other words, if you have a 7psi wastegate spring (in your external wastegate) or you have internal wastegate that is pre-tensioned to 7psi then you should only be able to create around ~14psi of peak boost pressure by locking down your EBCS @ 100% WGDC. Of course, your actual results may vary based on how well you have located your external wastegate, or how well the internal wastegate is ported, what size of restrictor pill you are using, what your turbine A/R is, etc.

Internal Wastegate Setup

Basic Internal Wastegate Setup

For basic mechanical set-up, you will need one vacuum line plumbed from the turbo compressor housing (pressure source) to the wastegate actuator nipple. This set-up uses no electronic boost control solenoid and will force the turbo to run on minimum, mechanical wastegate spring pressure.

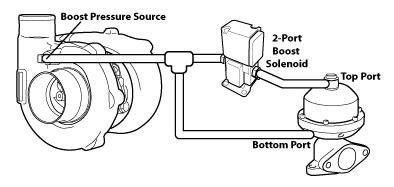

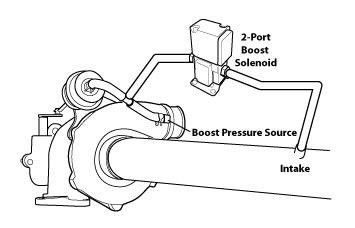

2-Port EBCS Internal Wastegate Setup, Bleed-type (used on the stock FI Subarus and EVOs)

For the mechanical set-up you will need one vacuum line plumbed from the turbo compressor housing (pressure source) to a vacuum T. The opposite side of the vacuum T will be plumbed to the wastegate actuator nipple. A 3rd vacuum line plumbs the middle of the T-fitting to port (1) of a 2-port wastegate solenoid valve. A 4th vacuum line will need to be plumbed from port (2) of the 2-port wastegate solenoid valve to the intake system, prior to the compressor inlet and after the air filter. This set-up uses a 2-port electronic boost control solenoid valve to bleed of air from the wastegate actuator. This set-up commonly uses a restrictor pill which is located in the vacuum line just off the compressor housing before the T-fitting.

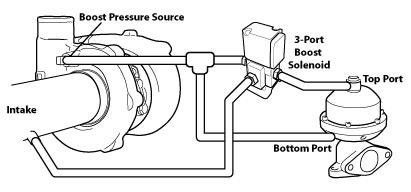

3-Port EBCS Internal Wastegate Setup, Interrupt-type

For the mechanical set-up, you will need one vacuum line plumbed from the turbo compressor housing (pressure source) to the pressure inlet port. If you blow through this port you should notice that air is coming out of one of the other two ports. Attach a 2nd vacuum line from the port which air comes out to the intake system, prior to the compressor inlet and after the air filter. A 3rd vacuum line should be connected from the 3rd port of the solenoid to the wastegate actuator. This set-up uses a 3-port electronic boost control solenoid valve to interrupt the air stream to the wastegate actuator. This set-up usually does not employ a restrictor pill which is located in the vacuum line just between the compressor housing and the solenoid valve, although a restrictor pill can be used here to help increase minimum WG pressure.

This set-up will increase the minimum boost pressure which is expected to run. We suggest you set all WGDC settings to zero so you can test your new minimum boost pressure achieved by this method of connection.

IMPROPER Internal Wastegate Setup

Having no pressure source vacuum lines attached to the wastegate actuator will force the wastegate valve to stay shut until the exhaust gas backpressure forces the wastegate valve open, which usually occurs at dangerously high boost levels.

External Wastegate Setup

Basic External Wastegate Setup

For basic mechanical set-up, you will need one vacuum line plumbed from the turbo compressor housing (pressure source) to the bottom port of the external wastegate. The top port is to be left open to the atmosphere. This set-up uses no boost electronic boost control and will force the turbo to run on minimum, mechanical wastegate spring pressure.

2-Port EBCS External Wastegate Setup

For the mechanical set-up you will need one vacuum line plumbed from the turbo compressor housing (pressure source) to a vacuum T. The opposite side of the vacuum T will be plumbed to port (1) of the 2-port wastegate solenoid valve. A 3rd vacuum line plumbs the middle of the T-fitting to the bottom port of the external wastegate. A 4th vacuum line will need to be plumbed from port (2) of the 2-port wastegate solenoid valve to the top port on the external wastegate. This set-up uses a 2-port electronic boost control solenoid valve to manipulate the air pressure going to the top port of the external wastegate. WARNING! This set-up will increase the minimum boost pressure which is expected to run. We suggest you set all WGDC settings to zero so you can test your new minimum boost pressure achieved by this method of connection.

3-Port EBCS External Wastegate Setup Option 1

For the mechanical set-up, you will need one vacuum line plumbed from the turbo compressor housing (pressure source) to a vacuum T. The opposite side of the vacuum T will be plumbed to port (1) of the 3-port wastegate solenoid valve. A 3rd vacuum line plumbs the middle of the T-fitting to the bottom port of the external wastegate. A 4th vacuum line will need to be plumbed from port (3) of the wastegate solenoid valve to the intake system, prior to the compressor inlet and after the air filter. The final and 5th vacuum line will need to be plumbed from port (2) of the 3-port wastegate solenoid valve to the top port on the external wastegate. This set-up uses a 3-port electronic boost control solenoid valve to manipulate the air pressure allowed to reach the top port of the external wastegate.

Customer Support

Phone support available 9am to 6pm Monday-Thursday. 9am to 4pm Friday (CST)

866.922.3059

Copyright 2023 © COBB Tuning Products LLC. All Rights Reserved. | www.cobbtuning.com

.jpg?version=1&modificationDate=1530025227824&cacheVersion=1&api=v2&width=350&height=220)