315600 - GR WRX, GR WRX STI, VA STI Flex Fuel Kit Installation Instructions

Congratulations on your purchase of the COBB Tuning Flex Fuel kit! The following instructions will assist you through the installation process. Please read them BEFORE beginning the install to familiarize yourself with the steps and tools needed. If you feel you cannot properly perform this installation, we HIGHLY recommend you take the vehicle to a qualified and experienced automotive technician.

IMPORTANT! Installing this kit will require custom tuning or utilizing an appropriate Stage Power Package map if you have a matching mechanical configuration. Please consult with COBB or an authorized ProTuner in your area.

Part List

- 1 x Flex Fuel Module

- 1 x Flex Fuel Sensor

- 1 x Long Assembled Fuel Line

- 1 x Short Assembled Fuel Line

- 1 x Mounting Bolt

- 3 x Small Zip Ties

- 2 x Medium Zip Ties

Tools Needed

- 5/16" or 8mm Fuel Line Disconnect Tool (Available at Professional Tool Sources)

- 7mm Nut Driver

- Flat Head Screwdriver

- 10mm Wrench

- 12mm Wrench

- 10mm Socket

- 12mm Socket

- Ratchet

- Pliers

- Diagonal Cutters or Scissors; (Hose Cutting tools suggested for straightest cuts)

- Safety Glasses

- Rags

- Silicone Spray or Similar

Important! Before removing your fuel line, make sure to discharge existing fuel pressure from the system. Failure to do so can result in fire, property damage, and/or death!

Removal of Existing Fuel Lines

The COBB Flex Fuel Kit is designed to work in harmony with the COBB Fuel Pressure Regulator Kit (STI only), as well as the fuel pressure sensor kit. These instructions assume you have already followed their instructions and properly installed both.

- Inspect the new components included with the COBB kit. If anything appears out of place, please contact COBB immediately and do not proceed with the installation.

- Make sure the engine is completely cool. Discharge the existing fuel pressure from the system. Consult the factory service manual for OEM methods. One potential method is to disable the fuel pump by pulling the fuse on the driver's side of the engine bay (consult the underside of the lid for correct fuse location), then attempt to start the vehicle. The vehicle will likely run for a brief moment and stall. Fuel pressure is reduced by this method, but some pressure may remain in the system.

- Disconnect the vehicle's negative battery terminal, then the positive battery terminal with a 10mm wrench or socket. Ensure no sources of spark or flame are present. Remove the battery from the vehicle.

- Prepare spill catch rags in case of fuel spills during line removal.

- Remove the existing return line that spans from near the manifold to the COBB fuel pressure regulator using 5/16" or 8mm quick-disconnect fuel line tool (e.g. AST #8028). Removal can be tricky, so please take your time. When done properly, the connector will easily slide off.

Installation of COBB Flex Fuel Sensor

- To install the COBB flex fuel sensor, first, remove the lower fuse box bolt shown below using a 10mm socket.

- Before you install the bracket, use a 10mm socket to loosen or remove the two other bolts that hold the fuse box in place. This will make installing the bracket with the stock screw much easier. Remove the lid of the fuse box by pushing in on the two tabs to access the bolts.

- Now you should be able to slide the slotted end of the bracket in between the fuse box and the chassis. Orient the bracket so the fuel connections are on the top, and the electrical connection on the bottom, facing the engine. Once the slot is lined up between the threaded hole in the chassis and the hole in the fuse box, re-install the stock screw in the same location as shown to sandwich the sensor bracket, and tighten. When tightening, make sure that you hold the bracket in the position shown.

- Reinstall the two other bolts that were removed from the airbox and clip back on the lid.

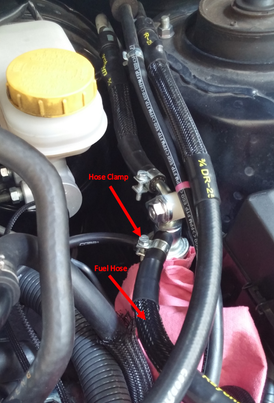

Installation of COBB Flex Fuel Kit Hoses

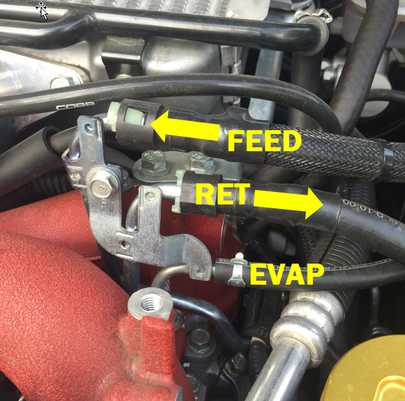

The COBB Flex Fuel Sensor installs between the manifold side fuel line connector and the regulator. In our example, we're using the COBB fuel pressure regulator, so we'll be installing the sensor on our return line before the new regulator hose. Our Flex Fuel Sensor and/or Fuel Pressure sensor do not restrict fuel flow and will not cause any hindrances. It's mandatory that you install either sensor pre-regulator to ensure accurate readings. The flow of fuel is as such:

- (STi): Fuel tank → firewall side fuel hard line connection point → intake manifold side fuel hard line connection point → fuel rail → combustion → manifold side fuel hard line connection point → (INSTALL SENSOR(S) HERE) → fuel pressure regulator → firewall side fuel hard line connection point → fuel tank

- (WRX): Fuel tank → firewall side fuel hard line connection point → (INSTALL SENSOR(S) HERE) → intake manifold side fuel hard line connection point → fuel rail (OEM fuel pressure regulator) → combustion → manifold side fuel hard line connection point → firewall side fuel hard line connection point → fuel tank

Instructions are similar for WRX, however, WRX users need to scroll to the "Amendment for WRX" section for a WRX specific connections.

- Installation of the long hose starts with placing the standard hose end with a clamp over the fuel pressure regulator barb. Secure the fuel injection clamp using a 7mm nut driver or flat head screwdriver. Ensure the hose clamp is close enough to the regulator body that it goes between the barb and body.

- Connect the other end of the longer fuel hose to the installed flex fuel sensor. The black and blue angled fitting will connect to the right side (toward the outside of the car) of the flex fuel sensor. To install the quick disconnect ends of the new hose, first fully clamp the two tabs and gently separate the clip from the hose. The parts will not separate until both tabs are fully pressed. Place the clip over the OEM fuel rail or line, "big side" first. Lubricate the new connector or line using silicone spray or similar, then gently slide the connector onto the fuel line until it clicks firmly in place. Note: DO NOT FORCE THE FITTINGS! Proper installation will require very little effort. The black connector and clip must be oriented in the same direction for the connector to seat. If the connector and metal line are not properly aligned, damage to the connector's inner seals can occur, which can cause fuel leakage.

- The shorter fuel hose will install in a similar fashion, but it will connect to the left side of the flex fuel sensor and the open fuel line on the manifold where your old return line used to attach. Start off by clicking the black and blue angled fitting onto the left side of the flex fuel sensor. You should be able to feel/hear a click when this is installed correctly. (NOTE: This picture did not include the installation of the longer fuel hose to the flex fuel sensor. Please pretend it's there in our picture.)

- To complete the install, take the open end of the shorter fuel line and connect to the open fuel line on the manifold side (or COBB pressure sensor fitting as shown, if present). You should be able to feel/hear a click when this is installed correctly.

- Finally, double check each step to make sure fuel lines are secure and that there are no leaks. Ensure that all spilled fuel has been cleaned up, and the rags are discarded far away from the vehicle being worked on.

- Fuel line feed/return orientation:

Installation of COBB Flex Fuel Module

The COBB Flex Fuel Module is designed to be bolted to the inter-cooler support bracket and plugged into the COBB Ethanol Sensor, in-line with the factory Rear O2 sensor and Tumble Generator Valve (TGV).

The Rear O2 connector obtains 12V power and does not alter the O2 sensor signal going to the ECU. The TGV connection allows the motor signals to pass through for those still using the factory TGV's, however, the feedback normally used to check TGV position is used to transmit Ethanol content data to the ECU (Engine Control Unit).

Mounting location may vary by customer/ installer preference, however, it is recommended to seal any unused connections from water intrusion, ideally by using the proper connector mate and using plugs to seal the mating connector.

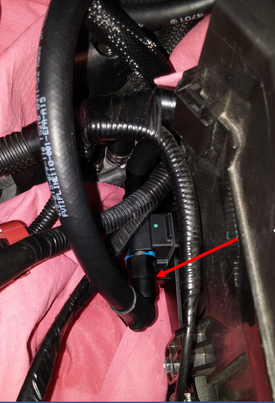

- Bolt the Flex Fuel module to the inter-cooler support bracket using the included bolt. Straighten the cables so that they aren't crossed over each other.

When plugging in connectors, make sure they are fully seated with a "click". - Pass the Flex Fuel Connector through the factory hoses and wiring harnesses and plug it into the Ethanol sensor. Ensure there is no strain on the connector, wiring, or the module.

- Pass the TGV Connector through the factory hoses and harnesses to the TGV valve on the driver's side of the vehicle toward the rear of the engine. Especially if on a lift, you may find this easier to do from the bottom of the vehicle where there's a clear path to the TGV. Ensure there is no strain on the TGV connector, wiring, or the module.

- Route the Rear O2 Connector to the bottom of the engine bay, then suitably raise and support the vehicle. Never work on a vehicle supported by a jack alone.

- Connect the Rear O2 Connector between the factory O2 sensor harness and the O2 Sensor connector.

- The O2 connector harness has extra length to work on a variety of vehicle configurations. Using the included zip-ties, secure the harness to the metal lines on the underside of the vehicle and in the engine bay. Ensure that the harness will not make contact with moving parts like the steering column, exhaust parts, and has sufficient slack between the engine and lines as well as lines and harness so that there is no strain as the engine moves.

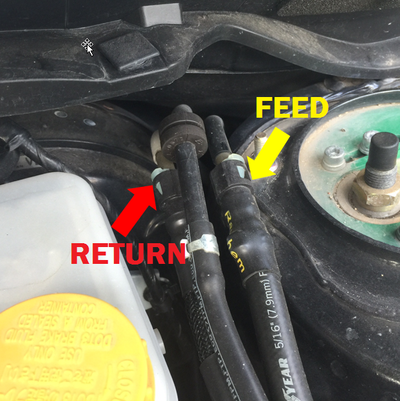

Amendment for WRX

While the assembly procedure is similar for the WRX, the following images show how the fuel lines are routed differently. The Flex Fuel Sensor will go in-line of the return line, and the Fuel Pressure Sensor will go in-line of the feed line (if purchased).

Regulator side:

The WRX Uses the lower connection (pictured) for a return - connect the barbed hose (no quick connect) here

Manifold side:

The upper quick connect on the manifold side is used for either the fuel pressure kit, if purchased

The bottom connection here is the return line (shown bending down to the fuse box), which will be used for the ethanol content sensor (in-line of the return flow)

Below is a completed configuration using R&D components:

Final Assembly

- Re-install the battery, ensuring that it does NOT make contact with the new fuel hose, as the sensor bracket is designed to press against the fuse box, but NOT make contact with the battery.

- Reconnect the positive terminal, and cover with the factory guard to reduce the risk of short-circuiting the battery. In case you missed the step above, make sure there is NO exposed fuel or rags near the car. Fumes can easily be ignited when connecting the battery.

- Reconnect the negative battery terminal and prime the fuel system by cycling the key between the "OFF" and "RUN" positions at 3-second intervals. 4 or 5 cycles will be adequate to re-pressurize the system. CAREFULLY INSPECT FOR LEAKS AND IMMEDIATELY CORRECT IF ANY ARE FOUND!

- Prime (Turn the key but do not start the engine until the fuel pump stops), then start the vehicle and again inspect for any leaking or abnormalities. Halt immediately if any fuel leaks or other issues are found!

- Installation of the Cobb Flex Fuel kit is now complete! We recommend inspecting for any signs of leaking or component deterioration periodically for safety and performance purposes. Enjoy your new COBB Flex Fuel Kit!

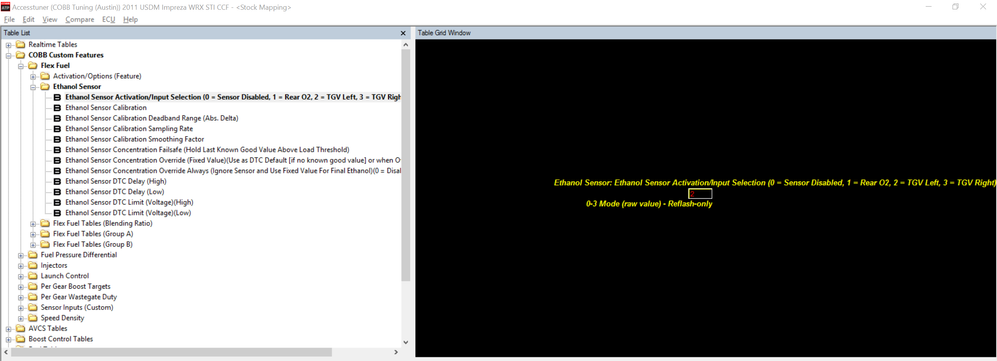

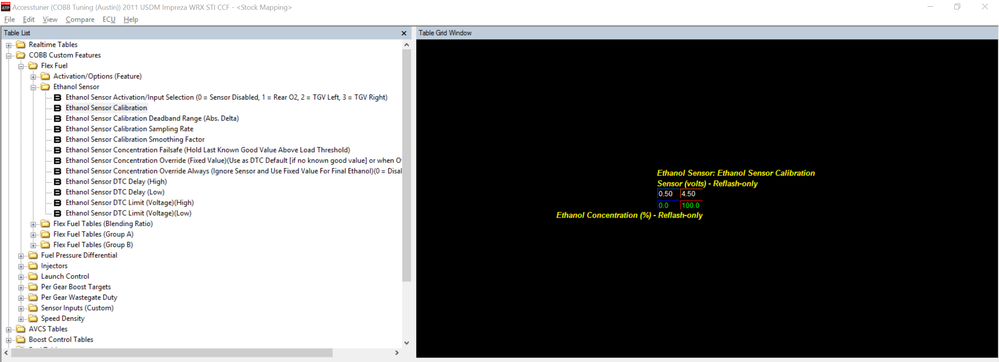

Calibration Data

Ethanol Sensor Input Selection = TGV Left

Sensor calibration:

0.5 V = 0% Ethanol

4.5 V = 100% Ethanol

Links

COBB Product Install Instructions for Subaru Vehicles

Main Installation Instruction Repository for Subaru Parts

Calibration Map Notes for Subaru Vehicles

Link to Subaru Map Notes to see what map you should be on given the parts you've added

COBB Customer Support Web Support and Tech Articles: COBB Tuning Customer Support Center Email: support@cobbtuning.com Phone support available 9am to 6pm Monday-Thursday. 9am to 4pm Friday (CST) 866.922.3059 return to www.cobbtuning.comContact Us:

Copyright 2024 © COBB Tuning Products LLC. All Rights Reserved. | www.cobbtuning.com

.jpg?version=2&modificationDate=1542320842473&cacheVersion=1&api=v2&width=710&height=399)

.jpg?version=1&modificationDate=1482864604164&cacheVersion=1&api=v2&width=712&height=1265)