512274 (long)

Universal Internal Wastegate Bracket Install Instructions

short: 2002-2008 WRX, 2004-2007 STI, 2004-2007 Forester XT

long: 2009-2014 WRX, 2008-2014 STI, 2009-2010 2.5 GT

***Warning: This part is only to be used in conjunction with an External Wastegate***

Congratulations on your purchase of the COBB Tuning Universal Internal Wastegate Bracket for your turbocharged vehicle! The following instructions will assist you through your installation process. Please read them first BEFORE beginning the install and familiarize yourself with the steps and tools needed. If you feel that you cannot properly perform this installation, we HIGHLY recommend you take the vehicle to a qualified and experienced automotive technician.

Part List

- Bracket

- Rod Linkage

- RH/LH "COBB" Sleeve Nut

- Spade Bolt

- 1/4"-28 Jam Nut

- 1/4" Flat Washer

- 1/4"-28 Lock Nut

- M8 Hex Bolt

- M8 Flat Washer

- M8 Lock Nut

Tools Needed

- 7/16" Wrench

- 1/2" Wrench

- 7/16" Deep Socket

- Ratchet

- Various Extensions

- 8mm Socket

- 10mm Socket

- Small Pick or Hook

Removal of Stock Wastegate Actuator

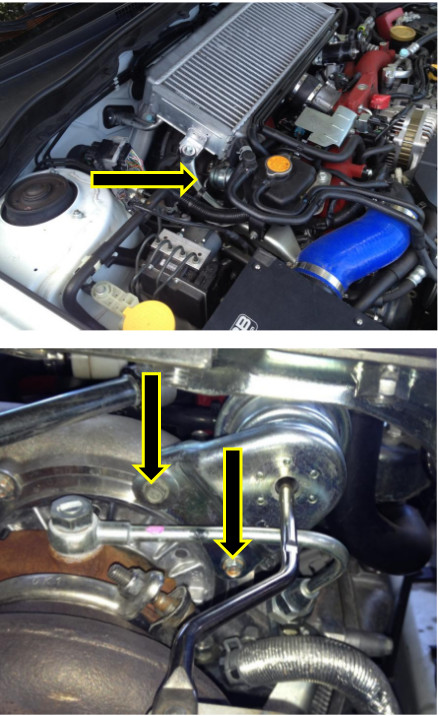

1. With the car cooled down, locate the factory wastegate actuator mounted on the turbo. Depending on the application, it is held to the compressor housing with either two or three 8mm or 12mm

bolts. Using a socket or wrench, loosen and remove the bolts to allow the wastegate actuator to hang freely.

3. Disconnect the vacuum line on the wastegate actuator and remove the actuator from the vehicle.

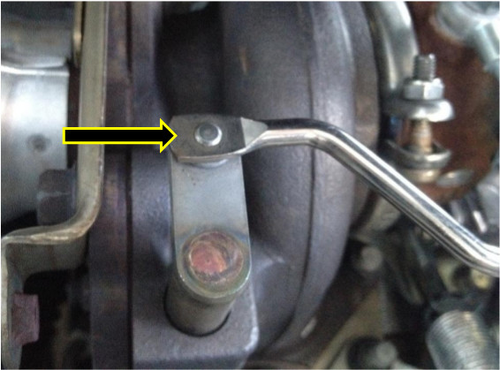

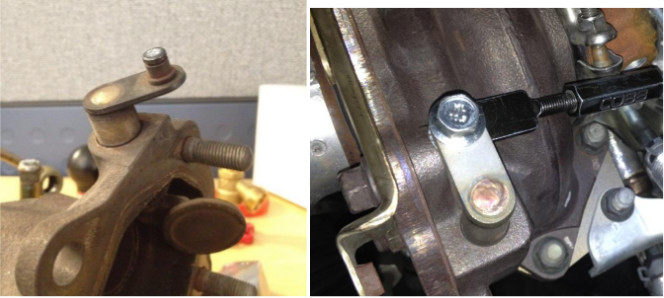

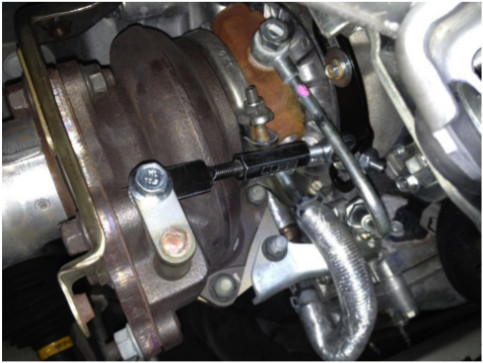

Installation of COBB Universal IWG Bracket

1. Depending on the application, there are three configurations that your IWG bracket is going to be mounted. Try them out and see which one works best for you. Most applications work well with Configuration A.

| Insert excerpt | ||||||

|---|---|---|---|---|---|---|

|